In today’s fast-paced business environment, some organizations view safety programs as potential roadblocks to productivity and profitability. They might choose to “do nothing” about safety to avoid perceived slowdowns or costs. However, this approach often proves to be a costly miscalculation that can significantly impact a company’s bottom line and long-term success.

To understand the real-world impact of safety decisions, we asked our KPA Connect customer community: “What’s one piece of advice you would give to an organization that’s hesitating to invest in safety because they’re concerned about costs or operational slowdowns?” Their responses, featured throughout this article, provide valuable insights from professionals who have experienced both the costs of inaction and the benefits of investment firsthand.

The Hidden Price Tag of Inaction

When organizations choose to ignore safety protocols or delay implementing proper safety measures, they expose themselves to various hidden costs that can far exceed the investment required for a robust safety program.

The High Cost of Ignoring Safety

Like many things, safety issues don’t disappear when we ignore them. Too often, companies are dinged with fines and violations because they shoved safety to the side. But what is the cost and risk associated with doing nothing?

Lost Productivity and Efficiency

While a “do nothing” approach to safety might seem to save time and resources initially, it actually creates significant productivity drains throughout an organization. Without proper safety systems in place, companies find themselves caught in a cycle of inefficient, reactive processes that consume valuable time and resources.

Safety managers, who should be focused on preventing incidents and improving workplace safety, often find themselves drowning in administrative bureaucracy. Studies have revealed that these professionals spend up to half their work week on manual paperwork, duplicate data entry, and managing preventable incidents—time that could be invested in proactive safety measures.

The problem extends beyond just the safety department. When organizations lack proper safety protocols, teams become disconnected, communication breaks down, and visibility into potential safety issues becomes clouded. This fragmentation not only impacts operational efficiency but also creates blind spots where safety hazards can develop unnoticed until they result in incidents.

“When implemented correctly, safety can prevent injuries, keep people at work, and increase productivity. When employees feel safe and appreciated, they will work harder and avoid absenteeism.”

– Matthew Bailey, EHS Manager, Alleguard | Watch the Alleguard Video Case Study

Regulatory Fines and Penalties

The cost of non-compliance continues to rise. Recent policy changes now allow citations for each instance of a violation rather than grouping them under a single citation. Maximum penalties can reach:

- $145,027 for willful or repeat violations

- $14,502 for serious violations

- $14,502 for other-than-serious violations

These fines can quickly multiply when multiple violations are discovered during an inspection.

The True Cost of Accidents and Injuries

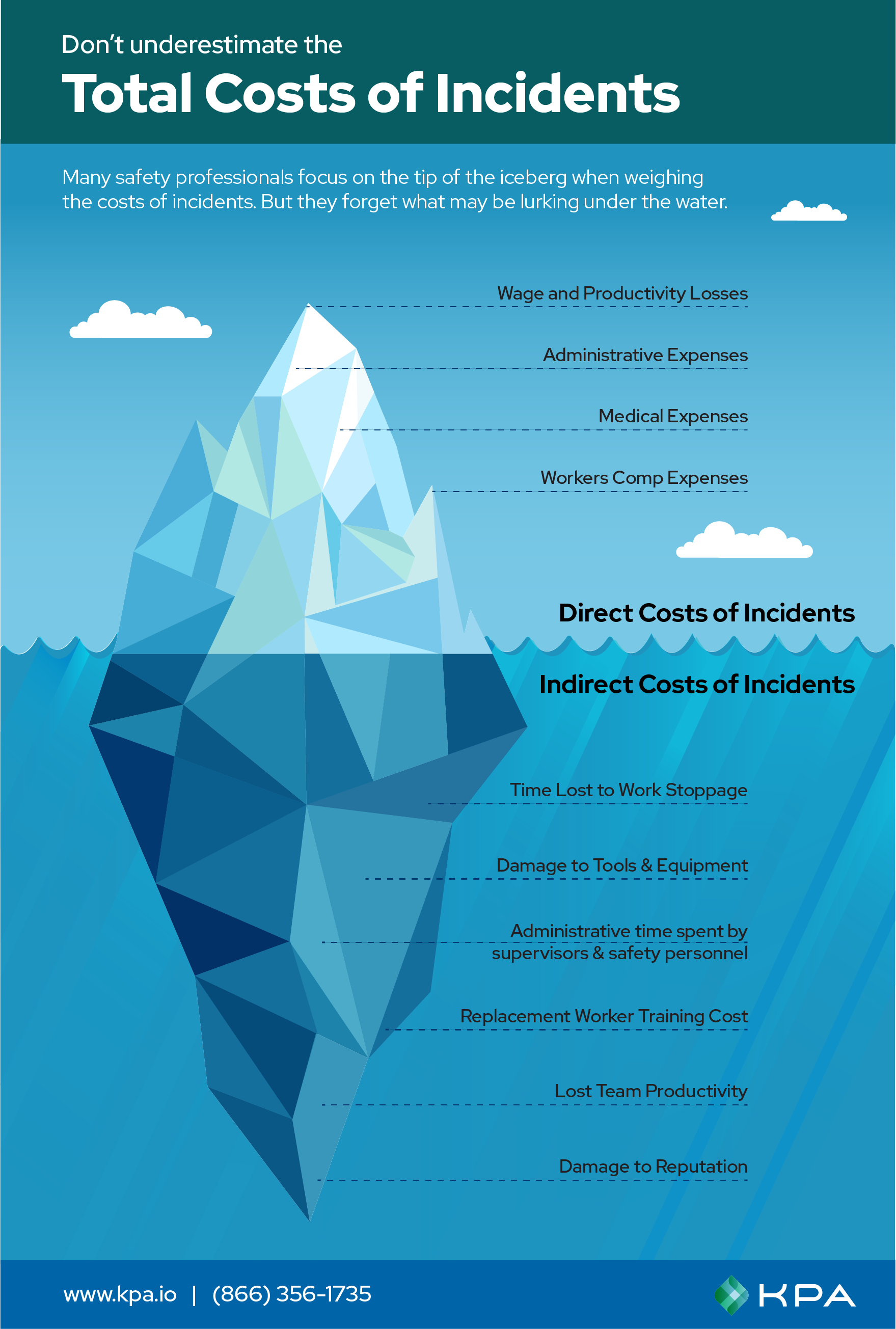

Workplace incidents carry both visible and hidden costs that can significantly impact an organization’s bottom line. Like an iceberg, the obvious direct costs represent only a small portion of the total cost, while the larger indirect costs often remain hidden beneath the surface.

The impact of these combined costs is substantial. According to the National Council on Compensation Insurance, the average workers’ compensation claim from 2019-2020 cost $41,353, with motor vehicle crashes representing the most costly type of incident at $85,311 per claim. When factoring in the indirect costs, which studies show can be 4-5 times greater than direct costs, a single incident can have a dramatic effect on an organization’s financial health.

Rising Insurance Premiums

When accidents occur, they affect insurance premiums for at least three years through the experience modification factor (e-mod). Poor safety performance leads to higher premiums, creating a long-term financial burden that could have been prevented with proper safety measures.

Damage to Company Reputation

Perhaps the most significant yet hardest to quantify cost is damage to company reputation. A poor safety record can:

- Hurt public image and brand value

- Make it harder to attract and retain top talent

- Reduce customer confidence

- Impact the ability to win new business

- Affect relationships with stakeholders

“Take a look at what was truly spent on injuries, including insurance costs, downtime, cost to serve, and even company reputation.”

– Bill Woods, Director of Safety, Quality and Regulatory Compliance, American Welding & Gas | Read the AWG case study

The Return on Safety Investment

When organizations invest in workplace safety, they see measurable returns that impact their entire operation. Studies from both OSHA and the National Safety Council consistently demonstrate that companies receive between $4 and $6 in return for every dollar invested in safety programs.

This return materializes across the organization in multiple ways. First, companies see immediate benefits through reduced incident rates and lower workers’ compensation costs. Insurance premiums often decrease as safety records improve, creating ongoing savings year after year.

Beyond these direct financial returns, organizations experience significant operational improvements. Employee engagement typically increases as workers recognize the company’s commitment to their well-being. This leads to higher productivity, better retention rates, and easier recruitment of top talent.

Companies with strong safety programs also report fewer regulatory inspections and citations, reducing both compliance costs and administrative burden. Perhaps most importantly, they build stronger reputations in their industries and communities, opening doors to new business opportunities and partnerships.

Transform Safety from Expense to Investment

Taking a “do nothing” approach to safety isn’t just risky—it’s expensive. While implementing proper safety measures requires an initial investment, the cost of doing nothing is ultimately much higher. Organizations that view safety as an investment rather than an expense position themselves for sustainable long-term success.

“It’s difficult to put an ROI on safety because, as we all know, safety is not an income stream. However, putting safety on the back burner will absolutely cost you money. Protect your real income stream by protecting the workers. Win-Win.”

– Chris Gafford, EHS Manager, Ring Energy

By implementing comprehensive safety programs, companies can protect their workers, their reputation, and their bottom line while creating a culture of continuous improvement that benefits everyone involved.

Remember: The question isn’t whether you can afford to invest in safety—it’s whether you can afford not to.

“The benefits of doing safety correctly greatly outweigh the cost of doing safety incorrectly.”

– Ryan Maraffi, Assistant Corporate Safety Director, Hatzel & Buehler

How KPA Helps You Move from “Do Nothing” to “Do Something”

At KPA, we understand that transitioning from reactive safety management to proactive safety investment can feel overwhelming. That’s why we’ve developed a comprehensive approach that combines easy-to-use software, expert consulting, and award-winning training to help organizations reduce the hidden costs of safety negligence while maximizing their return on investment.

Our flexible software platform eliminates the administrative burden that consumes up to half of safety managers’ time, freeing them to focus on preventing incidents rather than managing paperwork. With streamlined incident reporting, automated compliance tracking, and real-time visibility into safety metrics, organizations can identify and address potential hazards before they become costly incidents.

But technology is only part of the solution. Our experienced consultants work alongside your team to implement best practices, ensure regulatory compliance, and develop customized safety programs that fit your specific industry and operational needs. Combined with our comprehensive training library, we help create a culture of safety that engages employees at every level.

The result? Organizations that partner with KPA typically see reduced incident rates, lower insurance premiums, improved productivity, and enhanced reputation—all while protecting what matters most: their people.

Ready to transform your safety program from a cost center into a competitive advantage? Request a demo today to see how KPA can help your organization move from “doing nothing” to doing safety right.

Related Content

Explore more comprehensive articles, specialized guides, and insightful interviews selected, offering fresh insights, data-driven analysis, and expert perspectives.