How Often Should You Inspect & Replace Your PPE to Keep Your Workers Safe?

Designed specifically to mitigate severe or fatal accidents, personal protective equipment (or PPE for short) is essential to keeping your workers safe on the job.

Knowing how often you should inspect and replace PPE can help to avoid job site injuries and fatalities.

Some PPE may not necessarily expire, but all protective gear must remain in good and safe working condition. For example, gloves with rips render them useless when working with chemicals. So inspect your PPE regularly and replace it when you find damage.

PPE doesn’t last forever. Wearing damaged, broken, or malfunctioning PPE could be as dangerous as not wearing any form of protection at all.

Types of PPE

There are many different kinds of PPE, with each piece designed for a specific job or working condition. Common types of PPE include protective gloves and eyewear, high visibility safety vests, steel toe boots or shoes, and hearing protection. Depending on the unique work environment and risks, additional PPE such as fall protection, full-face shields, and respiratory equipment may also be required.

PPE is mandatory according to OSHA, and you should provide it to your employees at no cost to them. It may seem an additional expense, but failing to provide adequate health and safety for employees ends up more expensive than replacing PPE such as a hardhat.

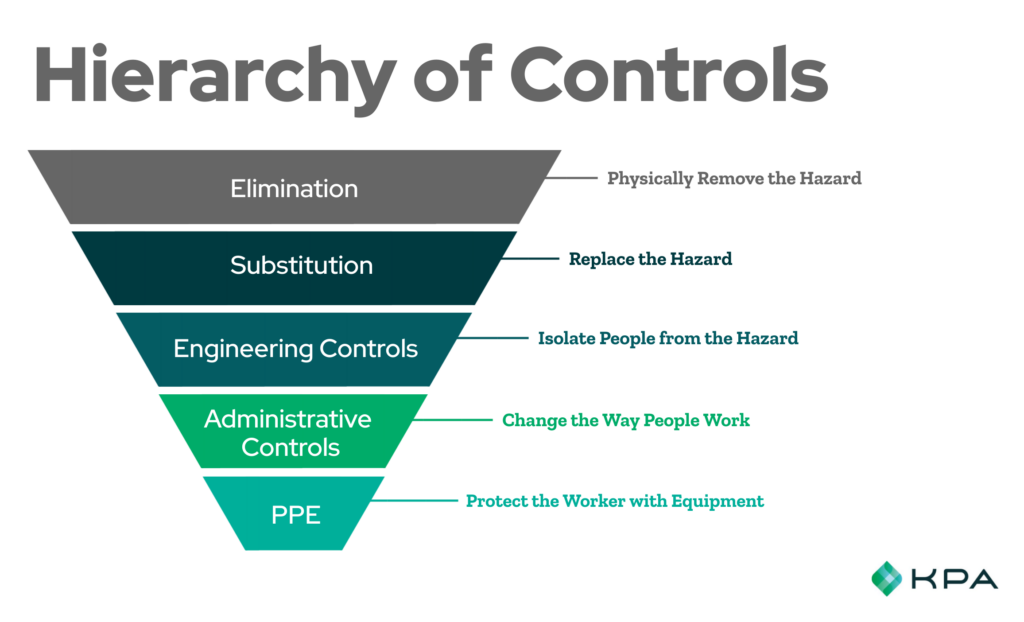

PPE is Your Last Line of Defense in the Hierarchy of Controls

The goal when using PPE is to stop injuries and fatalities, and although PPE is considered the last element on the hierarchy of controls, it is just as important.

Signs That Your PPE Needs Replacement

- The expiration date indicated by the supplier has expired or is nearing expiration

- Rips, tears, holes, or visible damage

- Discoloration or material degradation

- The number of owners the gear has had or how long it has been in use

- Missing components

- Failing straps, locks, adapters, or security devices

What’s Your PPE Inspection Plan?

Companies should have an annual plan to inspect their crew’s PPE to ensure it is in good condition and not expired. Inspectors should identify potential damage and failure points. If you find defective or damaged PPE, take the gear out of use right away. Companies should have extra replacement PPE handy for when this occurs.

Keep in mind, PPE stored for a long time may have deteriorated, even if they were not often used. Think of the news stories of the N95 masks held in the US national stockpile during the height of COVID-19. Deterioration can also happen with some PPE, like fall protection equipment.

OSHA recommends inspecting PPE before each use. For some equipment, like safety harnesses, OSHA has requirements regarding inspection, handling, and acceptable condition. Make sure your employees understand these requirements and that they’re following them at all times. Replace safety equipment like fall protection or hard hats if they’re involved in saving an employee from a serious fall or taking the brunt of an impact. OSHA requires employees to inspect personal fall protection systems before initial use during each work shift for mildew, wear, damage, and other deterioration. Make sure you remove defective components from service.

Making the Most of Your PPE

Not all personal protective wear is the same. Here are some tips for making the most out of your PPE:

- Always buy authentic PPE

- Train workers so they understand the proper fit and use and why using PPE is important

- Always properly store PPE (for example, away from the sun, chemicals, and other hazards which can compromise its integrity)

Tips for Ensuring Workers Wear PPE

Unfortunately, every year, completely preventable deaths or serious injuries occur from workers not wearing PPE or not using it properly. Here are some tips to encourage workers to wear PPE with 100% compliance:

- Lead by example – always wear proper PPE, even if you’re only on-site for a short period

- Adopt safety and PPE use as core values

- Choose comfortable gear – uncomfortable gear is cited as a top reason why workers don’t wear PPE – for example, choose gloves with an outer protective layer and a comfortable inner lining material.

- Create a culture of accountability where workers are comfortable keeping one another accountable for wearing proper PPE when needed

- Enforce policies when necessary

- Always have plenty of PPE conveniently available to your workforce

- Post signage showing what kind of PPE needs to be worn at each site location

Don’t fall victim to one of OSHA’s top 10 citations.

Save yourself time and headaches while keeping your employees safe. KPA can help ensure you have the processes in place to stay off of OSHA’s radar. Have questions? Looking for more information about OSHA’s PPE regulations? KPA’s here to help.

Read up on all of the top violations in the

OSHA Top 10 Resource Hub