Not surprisingly, the list’s actual violations stayed the same as the previous year, though some standards moved up or down. Respiratory Protection, which ranked seventh in FY 2023, climbed three spots to No. 4. Scaffolding fell four spots to No. 8.

“What’s more precious than our lungs?” Scott Ketcham, director of OSHA’s Directorate of Enforcement Programs, mentioned while presenting the list at this year’s NSC Safety Congress & Expo.

Not surprisingly, the list’s actual violations stayed the same as the previous year, though some standards moved up or down. Respiratory Protection, which ranked seventh in FY 2023, climbed three spots to No. 4. Scaffolding fell four spots to No. 8.

“What’s more precious than our lungs?” Scott Ketcham, director of OSHA’s Directorate of Enforcement Programs, mentioned while presenting the list at this year’s NSC Safety Congress & Expo.

Here’s the complete list:

Let’s Take a Look at OSHA’s Top 3 Violations

#1. Fall Protection

It is not unexpected that fall protection stayed at number one, with 5,424 total violations. Fall protection, or the lack of it, continues to be a problem at many job sites. It has been the most cited regulation for ten straight years. In 2019, there were 800 fatal falls in the US, and they continue to be the leading cause of death in the construction industry, according to Bureau of Labor Statistics data. Many employers are simply not providing workers with protection when it comes to falls, whether from a rooftop, a scaffold, or a ladder. Employers are also doing a poor job of training workers when it comes to preventing falls. Fall prevention training was number eight on OSHA’s list.

Learn how to keep your workers safe and comply with OSHA’s fall protection and training standards.

#2. Hazard Communication

HCS violations usually happen because of the complexity and paperwork involved in compliance. Organizations may fail to label their chemical containers properly, leave certain substances off of their chemical inventory lists, neglect to obtain SDS from manufacturers, or some combination of the above.

Read: What You Need to Know About Hazard Communication

#3. Ladders

Most ladder-related injuries and deaths are falls. Perhaps a worker slips on a wet rung of a fixed ladder erroneously stands on the top rung of a step ladder and loses their balance, or comes crashing down with a poorly-supported portable ladder. Each of these is an example of a preventable incident—and an OSHA violation.

Check it out:

Read up on all of the top violations in the OSHA Top 10 Resource Hub

How to Avoid the OSHA’s Top 10 and Other Citations

Do any of the regulations on the list apply to your workplace? If so, you should thoroughly review the standards and ensure you are complying with all employer requirements. Be prepared in case OSHA knocks on your door.

There are several steps your company can take to both avoid OSHA fines and prevent worker injuries, illnesses and deaths. Developing and enforcing a comprehensive safety program is your key to success.

Your safety program should include:

- Written Safety Programs

Develop and maintain written safety programs covering the hazards to which employees may be exposed. OSHA requires written safety programs and looks to see that they’re reviewed and updated annually. Make sure they are available to all employees. - In-depth Safety Training

Both new hire and annual safety training should cover all the risks workers are exposed to on the job site. Staff should be aware of the risks associated with their jobs, especially when working at heights, with hazardous chemicals, or with dangerous machinery. - Periodic Jobsite Inspections

Conduct inspections to identify hazardous conditions at the worksite. Most job sites require frequent monitoring and observations to stay on top of safety issues. Inspections identify hazards and provide opportunities to fix problems before injuries and accidents can occur. - Safe Tools and Equipment

Provide safe tools and equipment and ensure workers inspect them regularly. Many workers rely on their tools and equipment to get their work done safely. Unsafe tools and equipment can mean a higher risk of serious accidents, including losing an eye or a limb. They can also lead to OSHA citations. - Personal Protective Equipment

Provide appropriate personal protective equipment, or PPE, to workers. Companies must pay for and ensure that workers have the necessary PPE, such as fall arrest systems, hard hats, respirators, and hearing protection, to do their jobs safely.

You Don’t Have to Manage Your OSHA Requirements Alone

Have questions? Looking for more detailed OSHA compliance guidance?

KPA is here to help.

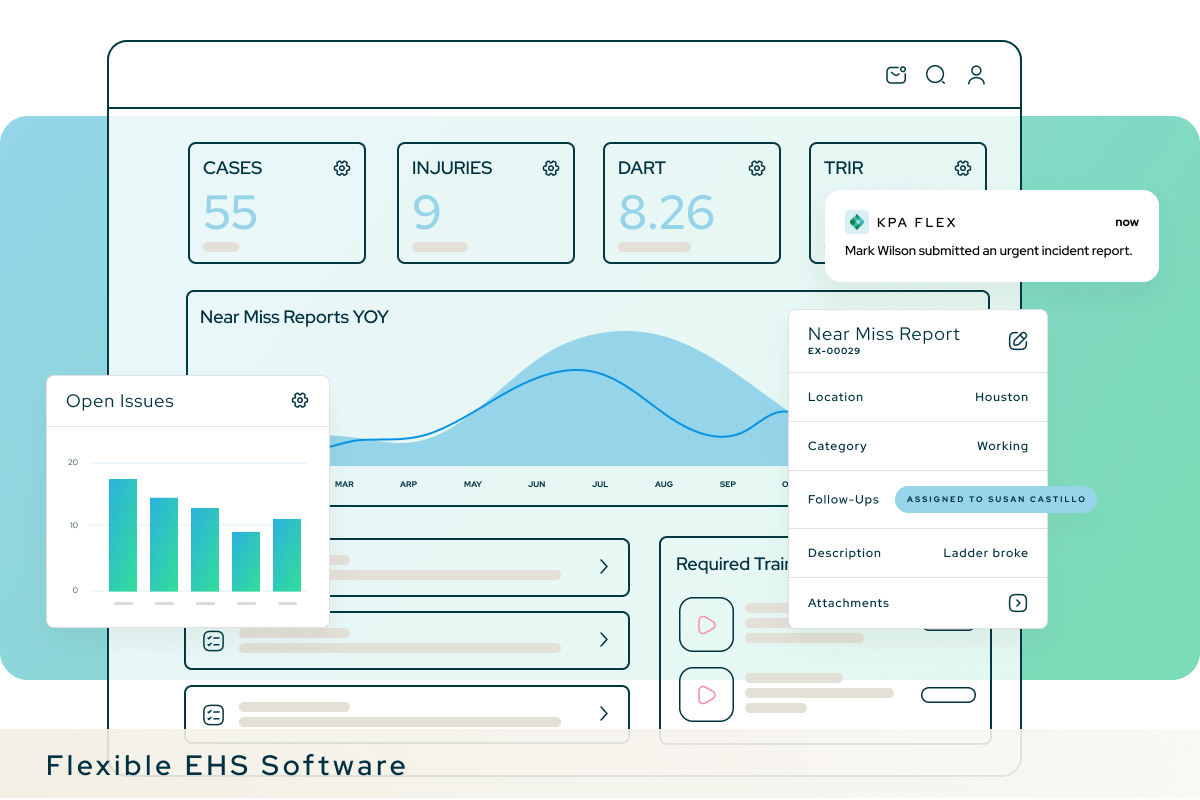

To truly protect your workforce and bottom line, you’ll need in-depth information—and not just about OSHA’s top 10, but every potential hazard that exists in your organization. You’ll also need to conduct a thorough evaluation of your facilities to identify current gaps and risk areas.

KPA’s unique combination of software, training, and consulting services can provide the coverage your people and your organization need.