Do you know everything you need to know about the most frequently cited Occupational Health and Safety Administration standards for the Construction Industry? In this series, we’re exploring the most common OSHA violations, one by one. Keep reading to learn how to avoid an OSHA job site inspection violation and protect your workforce from risks.

OSHA’s Jobsite Inspection Standard: What It Is

OSHA definition:

OSHA’s regulation “General Safety and Health Provisions (29 CFR 1926.20)” covers job site inspections. It states that “Such programs shall provide for frequent and regular inspections of the job sites, materials, and equipment to be made by competent persons designated by the employers.”

Simple definition:

Employers must regularly inspect job sites, equipment, and materials to ensure the safety of workers. A competent person must conduct the inspections.

Who’s Considered a Competent Person?

OSHA defines a “competent person” as “one who is capable of identifying existing and predictable hazards in the surroundings or working conditions which are unsanitary, hazardous, or dangerous to employees, and who has the authorization to take prompt corrective measures to eliminate them” (29 CFR 1926.32(f)).

By way of training and/or experience, a competent person is knowledgeable of applicable standards, can identify workplace hazards relating to the specific operation, and has the authority to correct them. Some standards add additional specific requirements that the competent person must meet.

Job Site Inspections

Safety inspections are the most effective way to identify hazardous conditions at the job site. Construction sites, in particular, require constant monitoring and observations to stay on top of constantly changing safety issues.

A good job site inspection program will identify potential OSHA violations, liability issues, and risk exposures. Jobsite safety inspections will identify safety issues and should include recommendations for addressing the problems. Periodic inspections are important because they identify hazards and provide opportunities to fix them before injuries and accidents can occur.

OSHA doesn’t specify how often job site safety inspections should be conducted, but at construction worksites, the need for inspection may be daily, weekly, or monthly. Inspections should also occur when major changes or events occur, like weather events, to identify hazards.

Inspection records should be maintained once inspections and corrective actions have been completed.

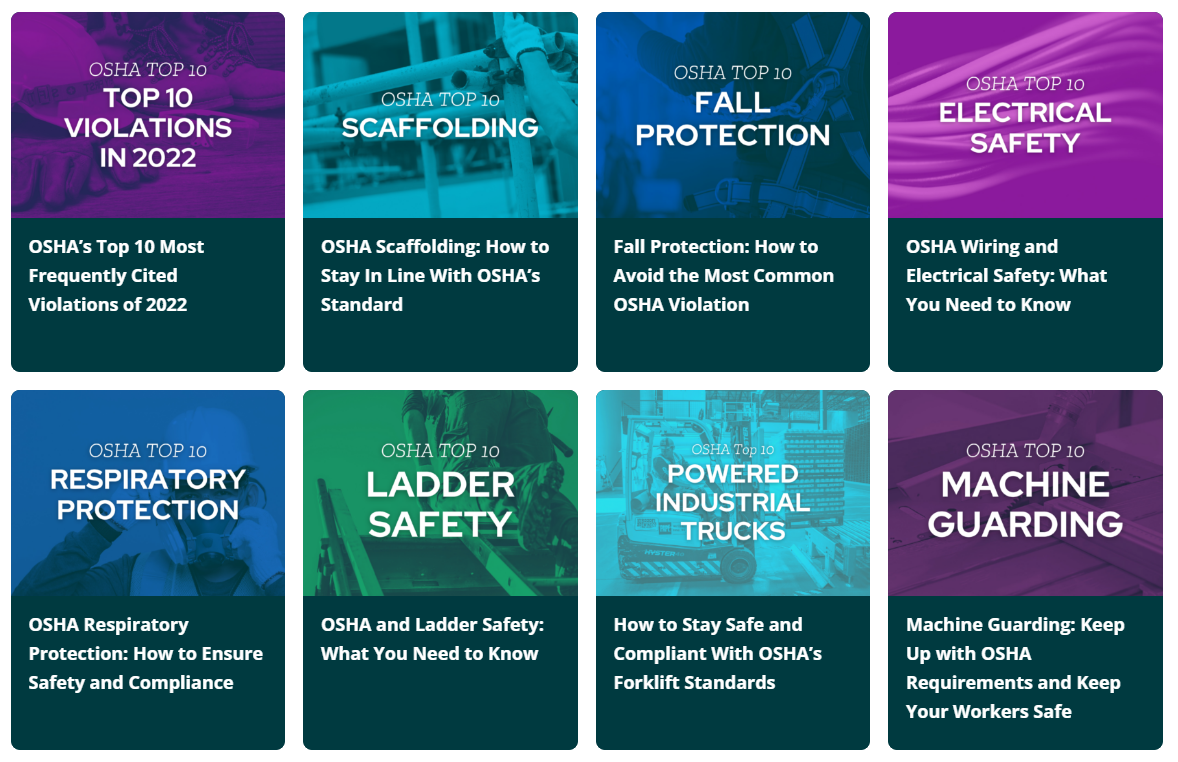

Read up on all of the top violations in the

OSHA Top 10 Resource Hub

What You Stand to Lose When Job Site Inspection Violations Happen

Direct costs:

OSHA penalties can exceed $15,000 per violation—and as much per day for every day the issue hasn’t been fixed by OSHA’s deadline. The fine for a willful or repeated violation can be ten times as much.

Indirect costs:

- Workers’ compensation claims from workers injured from a fall

- Lost productivity during and after an incident

- Legal and compliance fees

- Decreased morale

- Negative publicity and reputational damage

Signs You’re at Risk of a Job Site Inspection Violation

Construction sites can be dangerous places with many hazards. Those hazards can include:

- Falls from heights

- Excavation/trench collapse

- Scaffolding or ladder collapse

- Electrical hazards

- Caught in moving parts and machinery

- Struck by falling or flying objects

- Injuries caused by repetitive motion

- Hearing damage caused by exposure to loud noises

- Exposure to hazardous chemicals

Every worker who works at construction sites needs to understand and identify the many risks and what should be done to prevent them. Training on hazard identification should be conducted annually. Additionally, workers should understand that they must report unsafe conditions to a supervisor right away.

How to Avoid a Job Site Inspection Violation: Your Prevention Checklist

Daily Inspections

Some daily inspections are required. For example, forklifts and respirators must be checked before each shift. Others are recommended by the equipment manufacturer, and some OSHA standards require that the manufacturer’s recommendations be followed.

Equipment operators should perform these inspections at the beginning of the shift for:

- Forklifts

- Aerial lifts

- Other machinery

- Slings

- Rigging

- Hand and portable power tools

- Personal protective equipment

Frequent Inspections

Some workspaces and equipment require “frequent” inspection. Equipment and areas subject to frequent inspection—typically at least weekly or whenever conditions change—include:

- Electrical power and lockout/tagout procedures

- Fall protection

- Trenches, excavations, and shoring

- Crane and operator certification

- Scaffolds

- Stairways and ladders

Monthly Inspections

Some OSHA standards require monthly equipment inspections, included are:

- Fire extinguishers

- Eyewashes and safety showers

- Cranes and hoists

- Emergency escape respirators and self-contained breathing apparatus

Job Site Inspections are Easier with EHS Software

With KPA EHS you can quickly deploy pre-built safety inspection checklists from a library of 50+ templates. Customize existing inspection forms or create your own. You can schedule ongoing or ad-hoc inspections and capture, assign, track, and report on issues to head off incidents or accidents before they occur.

For more information and guidance about job site inspection violations, contact us.