Compliance with OSHA’s Hazard Communication Standard (or HCS for short) is not a one-shot deal. You’ll need to determine who’s responsible for both the initial and ongoing activities needed for compliance. We’re here to help you get this process rolling.

Start by assigning a Program Manager with overall responsibility for your hazard communication program.

This will ensure you always have ongoing oversight and accountability. HazCom Program Managers are responsible for executing the requirements of this program so that all persons safely work with hazardous chemical products in their work areas.

Your Program Manager will most likely be in charge of:

- Auditing and monitoring the effectiveness of the program

- Developing the training program and monitoring its effectiveness

- Monitor facility for proper use, storage, and labeling of chemicals.

- Maintaining the Chemical Inventory, ensuring the company has access to the proper safety data sheets (SDS for short)

- Ensuring DSs are readily accessible to employees and medical personnel at all times

- Addressing corrective actions in a timely fashion.

But Your Program Manager’s Not Alone

Your Purchasing staff should serve as “gatekeepers” to control all incoming and outgoing chemical products utilized on-site.

This can include ensuring

- all received containers are properly labeled per GHS and that these labels are not removed or defaced.

- all shipped containers are properly labeled.

- they have SDSs for all chemicals purchased from retail and all other sources before these chemicals are allowed on site.

- Received SDSs are properly obtained and distributed.

Your Department supervisors should help reinforce the Hazard Communication program, ensuring their employees understand both the “how” and the “why” of the program. They need to make sure their team only uses the chemicals for which they’ve been trained and that they’re using them in the proper manner.

Work with contractors? Contractor management needs to coordinate with the program administrator to ensure contracted employees are properly trained and comply with the program:

- Ensure that contracted employees are properly trained.

- Notify the organization before bringing any chemicals into any facilities.

- Monitor and assure proper storage and use of chemicals by contracted employees.

Employees and contracted employees need to:

- Follow the program requirements.

- Be familiar with the chemicals they work with, including reading the labels and accessing the SDSs.

- Report any problems with the storage or use of chemicals.

- Report chemical spills or suspected spills.

Enhancing Hazard Communication: Practical Steps for Success

Take your hazard communication program to the next level. This webinar focuses on actionable strategies to improve and sustain an effective hazard communication program.

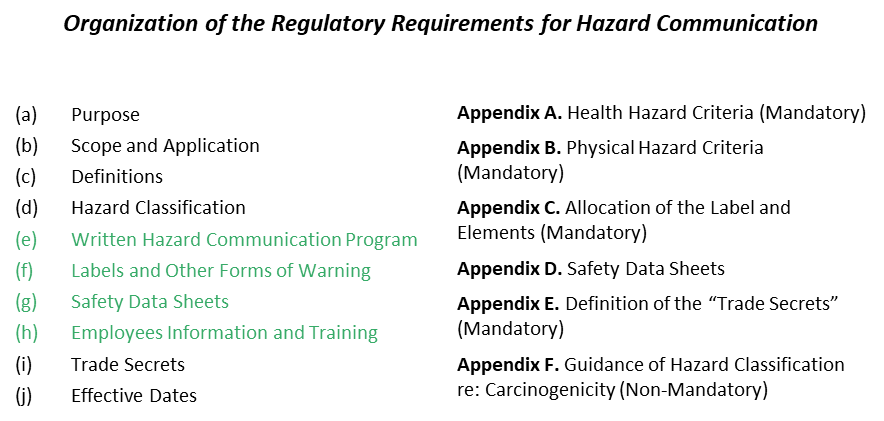

Getting to Know the OSHA Hazard Communication Standard

OSHA’s Hazard Communication Standard (29 CFR 1910.1200) details the chemical hazard information that employers need to share with employees. It covers all industries where employees are potentially exposed to hazardous chemicals and outlines a common and coherent approach to classifying chemicals and communicating hazard information.

All employers have four primary requirements

- Written Hazard Communication Program

- Labels and Other Forms of Warning

- Safety Data Sheets

- Employee Information and Training

Note that the HCS specifies two types of work operations where the rule’s coverage is limited: laboratories and operations where chemicals are only handled in sealed containers (e.g., a warehouse). These employers have reduced obligations to employees under the HCS and only need to:

- Keep labels on containers as they are received

- Maintain Safety Data Sheets (SDSs) that are received and give employees access to them

- Provide information and training to employees

When those companies act as chemical manufacturers, distributors, or importers, they must fulfill their duties as suppliers by providing compliant labels and SDSs to downstream customers at the first shipment and when the SDS is updated.

Understanding Hazard Classifications

Manufacturers must provide hazard information in the form of labels and SDSs when shipping chemicals to users. The information must provide the identities and hazards of the chemicals, their characteristics and properties, and how to prevent potential adverse effects.

A “hazardous chemical” means any chemical classified as a physical hazard or a health hazard. The HCS refers to each of the following threats as a “hazard class.”

Most hazard classes are further divided into one or more “hazard categories” based on the severity of the effect and correlate to information provided on labels and SDSs. For example, an SDS form for a flammable liquid will include category-level criteria (in this case, related to flash point).

Ok, you’ve established your team.

You understand the HazCom Standard.

What’s next?

Now it’s time to get your plan on paper. Sorry to leave you on a cliffhanger, but join us next week to learn how to develop a Hazard Communication Written program.

How KPA Helps Strengthen Your Hazard Communication Program

KPA is here to help you maintain a comprehensive Hazard Communication program.

HazCom Written Program

KPA’s expert EHS consultants will help you develop a written program that is tailored to your business. It will include everything OSHA looks for including:

- A list of all the chemicals present in your workplace

- How and where employees can access Safety Data Sheets

- Identify the individual designated as responsible for the oversight of your program

Hazard Communication Awareness Training

KPA also provides online and on-site Hazard Communication training. Courses for both employees and managers cover how information about hazardous materials is communicated in the workplace. They also include information about how to read hazard labels and safety data sheets as well as the importance of the written program and training.

SDS Management

Ensuring your employees have quick and easy access to Safety Data Sheets may be the most important component of your Hazard Communication program. With KPA EHS you have access to a database of over 70 million datasheets. You can create your own SDS folders and custom SDS library with an easy to search interface. You’ll also have offline access and hardcopies to ensure all your staff can easily find SDSs. Finally, you can print pre-populated secondary container labels for GHS compliance.

Related Content

Explore more comprehensive articles, specialized guides, and insightful interviews selected, offering fresh insights, data-driven analysis, and expert perspectives.