If you spent 2025 feeling like you were always one step behind—scrambling after incidents, pulling together reports at the last minute, or piecing together data from a dozen different sources—you’re not alone. That reactive cycle is exhausting, and it keeps you stuck in firefighting mode instead of doing the strategic work that actually prevents incidents.

The good news? The year-end is the perfect time to break that cycle. The lessons you learned in 2025—even the painful ones—are exactly what you need to build a stronger, more proactive approach for 2026.

Measure What Matters eBook

Your guide for establishing effective safety program KPIs. As organizations continually strive to improve their safety standards, the role of Key Performance Indicators (KPIs) in shaping an effective safety program is more crucial than ever.

Reflecting on 2025: An Honest Assessment

Before you can plan where you’re going, you need to understand where you’ve been. Take an honest look at your 2025 safety program and ask yourself these questions.

The goal isn’t to collect more data. It’s to collect the right data in a way that actually helps you see problems before they become incidents.

From Lagging to Leading: The Indicator Shift

If you’ve been measuring safety success primarily through TRIR, DART, and incident counts, you’ve been looking backward. These lagging indicators tell you what already happened. They’re required for compliance and useful for benchmarking, but they don’t help you prevent the next incident.

Leading indicators are different. They measure the activities and conditions that predict future performance. When you track them consistently, you can spot problems early and intervene before anyone gets hurt.

The shift from lagging to leading indicators is the difference between being reactive—”we had three incidents last month”—and being proactive—”near-miss reports in the welding area tripled, which tells us we need to act now.”

Step-by-Step: Setting Up Leading Indicator Tracking for 2026

You don’t need to overhaul everything at once. Start with a few key leading indicators and build from there.

Year-End Reflection Worksheet

Assess your 2025 journey. Plan your 2026 strategy.

2025 Performance Review

What were your top three safety wins this year?

What were your biggest challenges or setbacks?

Which incidents or near-misses surprised you—and what data might have predicted them?

Where did you spend the most time on manual, repetitive tasks?

Data and Systems Assessment

Where does your safety data live today? (List all locations: spreadsheets, paper files, software systems, email.)

What questions can't you answer because the data is scattered or incomplete?

How long does it take to pull together a report for leadership?

What visibility do you have into real-time safety status across your facility?

2026 Planning

What two to four leading indicators will you track?

What baseline targets will you set?

What process changes are needed to make data collection easy?

How will you review and act on leading indicator data each week?

How Technology Supports the Shift

You can track leading indicators with spreadsheets. But if you’ve tried, you know how quickly that becomes its own full-time job. Manual data entry, version control headaches, and the constant struggle to get information from the field into a usable format—it adds up.

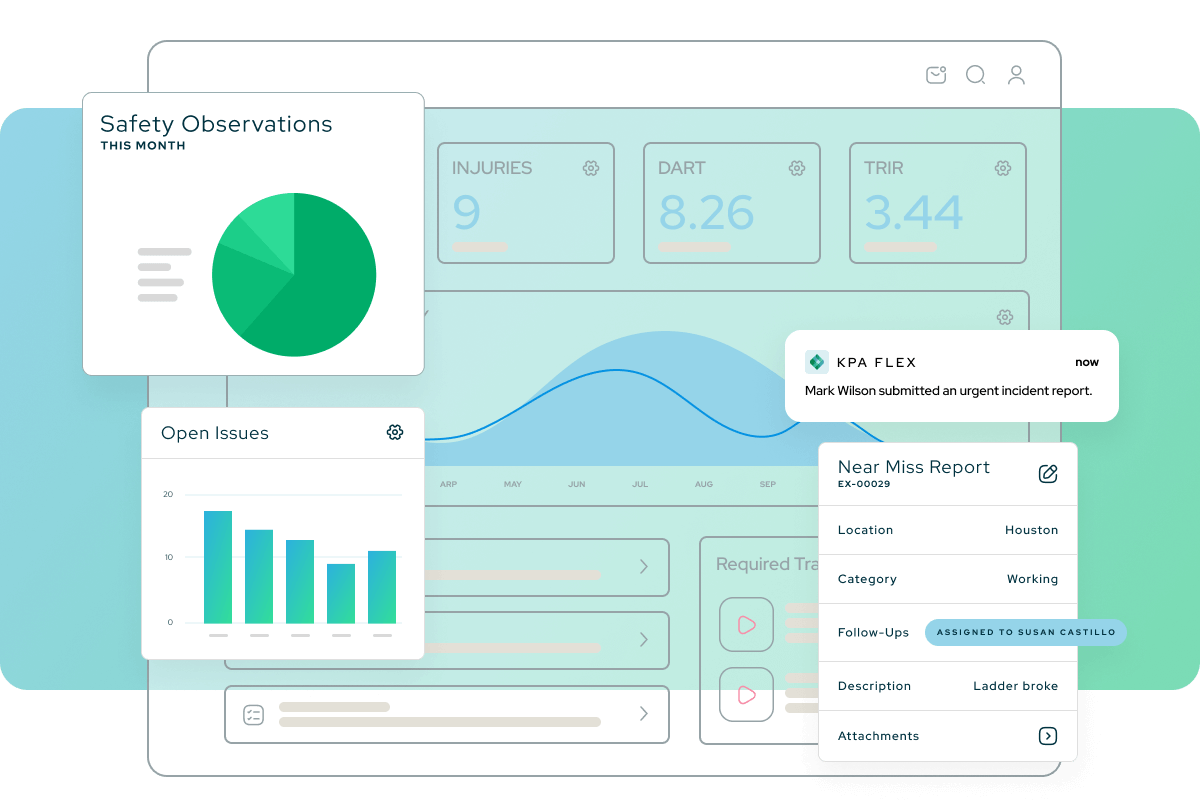

This is where a flexible EHS software platform makes a real difference. KPA Flex is built for exactly this kind of work. The platform lets you create custom metrics tailored to your specific industry and risks, so you’re tracking what actually matters for your operation.

The Flex mobile app brings data collection to where the work happens. Supervisors can complete behavioral observations from the floor. Workers can report near-misses in seconds. Inspections capture photos, timestamps, and GPS data automatically. All of it flows into a central system where you can see trends, spot problems, and generate reports without manual compilation.

Real-time visibility changes everything. Instead of waiting for weekly reports, you can see inspection completion rates, open corrective actions, and near-miss trends as they happen. That’s the foundation of proactive safety management.

Making 2026 Different

The reactive cycle is hard to break. There’s always another urgent email, another compliance deadline, another incident to investigate. But every hour you spend firefighting is an hour you’re not spending on prevention.

Use what you learned in 2025. Identify your data gaps. Pick a few leading indicators that matter. Build a collection process people will actually use. Review the data regularly and act on what you find.

This isn’t about perfection. It’s about progress. Move from stressed and reactive to confident and proactive—one indicator, one process improvement, one decision at a time.

You’ve got this.

Related Content

Explore more comprehensive articles, specialized guides, and insightful interviews selected, offering fresh insights, data-driven analysis, and expert perspectives.