Manufacturing

EHS Software for

Manufacturing Safety

Reduce risk and improve workplace safety across your supply chain and locations. Streamline operational efficiency with our comprehensive safety management software for manufacturing that ensures compliance and worker safety.

Safety Software Built for Manufacturing Excellence

We offer a complete safety management system for the manufacturing industry that centralizes workplace safety with user-friendly inspection tools, incident management, real-time reporting, and analytics. Our manufacturing safety software helps you minimize hazards and optimize productivity while maintaining OSHA compliance.

SOFTWARE FEATURES

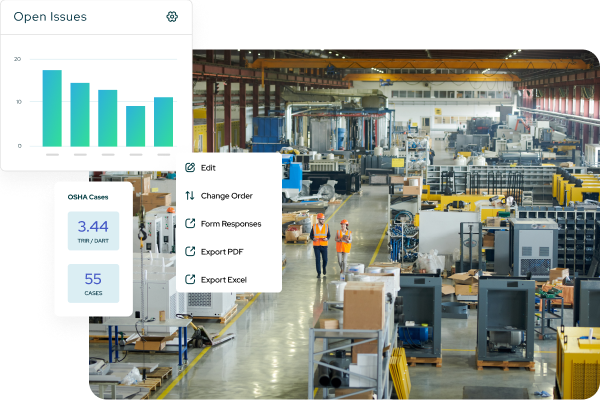

Flexible EHS Management Software

KPA’s highly configurable EHS software allows you to tailor the system to your team’s processes, creating a unified system that drives safety culture across manufacturing environments.

Customize Your Safety Program

Quickly digitize and deploy EHS forms including safety inspection checklists, incident reporting, and hazard assessments with our powerful form builder. Streamline safety documentation and ensure compliance with safety regulations and standards.

Real-Time Reporting and Analytics

Analyze your safety data to take corrective and preventive actions and optimize risk mitigation strategies. Configure dashboards to monitor safety metrics and track operational efficiency and continuous improvement.

Mobile Safety Management

Access reports, training management resources, and safety data in the field. Improve workplace safety with real-time incident reporting and complete safety inspections on the manufacturing floor.

SOFTWARE FEATURES

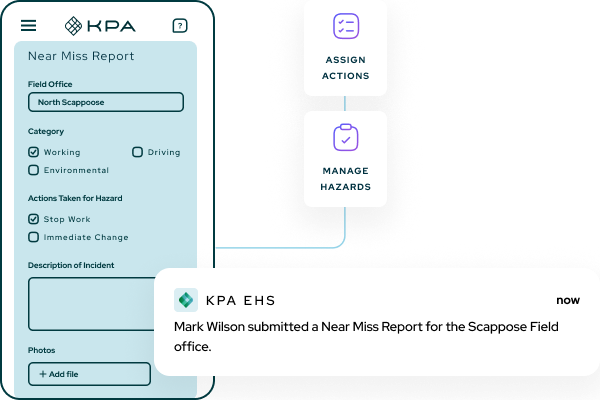

Incident Management Designed for Manufacturing Safety

Get instant insights into potential workplace hazards before they result in serious incidents.

Real-time reporting

Your teams can submit near-miss reports, incident reports, BBS, and JSA reports that give you instant insights into potential issues before they result in a serious accident.

Immediate notifications

Get instant incident reports through email or push notification so you can stay on top of what happened and begin taking action.

Flexible to fit your workplace

Quickly deploy pre-built safety inspection checklists from a library of 50+ templates.

SOFTWARE FEATURES

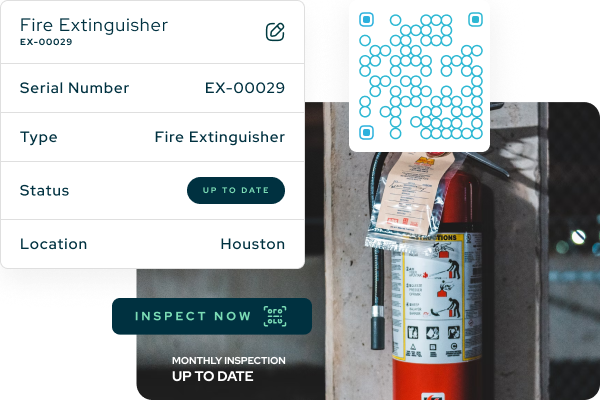

Equipment and asset inspections

Complete inspections through a configurable form on the mobile app so you can report your findings in real-time from the production floor.

QR code assignment

Because asset is assigned a QR code, scanning and verifying allows team members to do a quick inspection in seconds.

Scheduled inspections

Set up and assign a schedule for inspections based on equipment or equipment type, frequency of inspections, expiration dates, and more.

Reporting and analytics

Run status reports at any time to see which assets have up-to-date, expiring, or already expired inspections.

SOFTWARE FEATURES

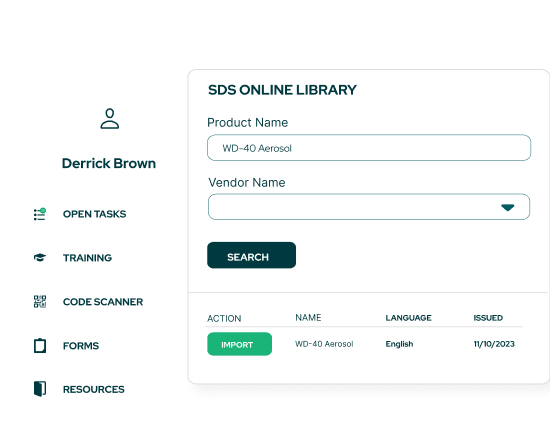

Multilingual support for manufacturing employees

With the click of a button, each employee’s profile can be set to English, Spanish, or any of the other 100+ languages currently supported.

Language preferences & translated content

- Online forms

- Inspections

- Training

- Acknowledgments/sign-offs

- Entire web application

100+ Languages

Encourage broader participation and inclusion in your safety culture.

Industry Specific Training

Manufacturing Safety & Compliance Training

We’ve transformed training in the manufacturing industry by providing targeted health and safety software that gives your teams the knowledge they need. Our safety management software for manufacturing delivers high-quality, interactive training that improves workplace safety and ensures compliance with safety regulations.

Through comprehensive monitoring of completion rates and assessment scores, our system enables effective training management across your organization. We provide customizable KPA courses tailored to your manufacturing environment, with helpful training resources available anytime. Stay ahead of the curve with the latest industry news and best practices in manufacturing safety.

Not seeing your industry here?

CONCRETE

Optimize safety in concrete operations and manufacturing environments where multiple workplace hazards exist, from dust and debris to mobile equipment and driver safety.

Our training catalog features industry-specific content encompassing essential aspects of cement mixer safety, comprehensive truck yard operations protocols, safe pallet lifting procedures, and proven manufacturing safety best practices. Our real-time monitoring ensures continuous improvement in workplace safety standards.

MILL SERVICES

Address critical safety challenges in the mill services industry, from molten slag handling to equipment safety protocols. KPA’s safety software streamlines inspection processes while enabling efficient incident reporting and management.

Our system helps implement effective corrective actions and maintain strict OSHA compliance through comprehensive safety management tools. The software provides real-time insights into safety metrics and operational performance.

PLASTICS

Protect workers in the plastics manufacturing industry with comprehensive safety management systems that address dangerous moving equipment and laceration hazards. Our safety program delivers extensive coverage of plastic pipe laceration prevention, truck yard facility safety protocols, and detailed equipment inspection procedures.

Through real-time hazard reporting and analytics, managers can proactively address safety concerns and maintain compliance standards across the manufacturing floor.

REBAR

Enhance manufacturing safety in the rebar industry with specialized EHS management solutions for hot work, bending tables, mobile equipment, and crane operations. Our comprehensive system integrates detailed safety inspection checklists with powerful incident management tools.

Through continuous audit and compliance tracking capabilities, organizations can maintain worker safety protocols while meeting regulatory requirements. The software provides real-time visibility into safety performance and operational metrics.

RECYCLING

Optimize safety in the dynamic scrap recycling industry where material handling and processing present continuous risks. Our manufacturing EHS software helps organizations minimize workplace hazards while ensuring compliance with safety standards.

Through integrated safety metrics tracking and operational excellence monitoring, companies can maintain high safety standards while improving productivity. The system provides comprehensive insights into safety performance and compliance status.

STEEL DISTRIBUTION

Drive safety culture in steel distribution with comprehensive safety software that addresses industrial shelving and equipment hazards. Our solution enables regular safety audits and implements effective risk mitigation strategies across operations.

Through detailed safety data analysis and preventive maintenance tracking, organizations can maintain high safety standards while optimizing operational efficiency. The system provides real-time monitoring of safety metrics and compliance requirements.

STEEL MANUFACTURING

Enhance safety in manufacturing with specialized software solutions for hot work and equipment operation. Our unified system delivers real-time incident reporting capabilities alongside robust safety inspection tools.

Through comprehensive compliance monitoring and analytics dashboards, organizations can track safety performance and identify areas for improvement. The software provides detailed insights into safety metrics and operational excellence indicators.

TUBE & PIPE

Improve workplace safety in tube and pipe manufacturing with focused training on hand awareness and machine guarding. Our software solution helps organizations digitize safety processes while centralizing compliance documentation.

Through systematic tracking of corrective actions and safety metrics, companies can maintain high safety standards and regulatory compliance. The system provides comprehensive monitoring of safety performance and operational efficiency across manufacturing environments.

Customer Spotlight

Learn how KPA customers are saving time and money while building a safer workforce.

The first thing that I did was start an SDS library. It’s dangerous out there. We have forklifts, cranes, and other heavy equipment moving around all the time. You don’t want anybody to get hurt.

Safety Director, Schurco Slurry

Recommended Resources

Stay ahead of manufacturing safety trends with these valuable resources.

3 Fail-Safe Strategies for Managing Safety Data Sheets

Learn how to build a consistent SDS maintenance routine and make SDSs an integral part of your safety culture.

EHS State of the Industry

Does your organization invest in EHS or does it see it as a necessary evil? The distinction matters. In partnership with EHS Today, KPA conducted an industry survey.