You don’t need a master’s degree in energy management to understand the danger that raw oil and gas can bring to a worksite. Those who work with oil and gas on an energy production site hold some of the most stressful and high-risk jobs on the planet.

Just like the construction industry, oil and gas workers have some basic workplace safety focuses—hand tools, PPE, fall protection, and the like. But oil and gas workers need to be aware of factors that may result in spills, explosions, and uncontrollable fires. Those in drilling also need to be prepared for the prevention of hazardous blowouts. A minor accident on an oil rig is not only incredibly costly but also potentially deadly for all those working on the site.

The Complicated E&P Worksite

The tasks found on an E&P worksite are delicate and complicated, forcing owners to hire upwards of a dozen different subcontractors to operate in the same space. And these subcontractors bring a myriad of tools, chemicals, and equipment with them to the job site.

These are difficult enough jobs on their own without the added worry of stepping on someone else’s toes or having your work interrupted by another group of subcontractors. But this is the unfortunate reality of the exploration and production industry.

Ideally, each subcontractor would be aware of what the other has been brought on board to do, and has been briefed on each and every potential safety hazard involved with their presence. A drill operator and a water tank monitor have two very different jobs, but when they work in such close proximity to one another, they should at the very least take steps to ensure they don’t get in each other’s way.

SIMOPS, short for Simultaneous Operations, is a catch-all term for this type of scenario. If job site managers, facility owners, and project owners are doing their jobs correctly, they should be aware of and prepare for the intricacies of all SIMOPS on the job site.

The Key to SIMOPS Success: Communication & Technology

As with all high-pressure, potentially hazardous work environments, a safe work site starts with effective communication.

All SIMOPS communications should come directly from the top. Contractors alone cannot be expected to gain a deep understanding of each person’s role on the worksite at any given time. The proper information and training can ensure that workers aren’t walking into hazardous scenarios that they may not fully be aware of.

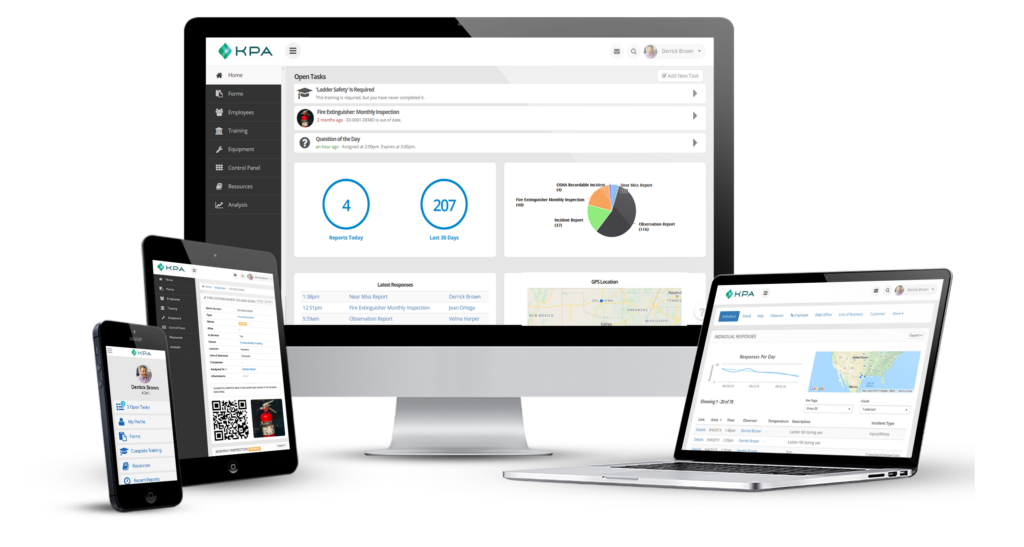

That’s where technology comes into play – particularly mobile technology. Look for EHS software that’s designed for easy reporting & training in the field. Your SIMOPS team, along with your employees and subcontractors, need real-time access to key components of your safety and compliance programs – even when they’re offline. Look for tools that take advantage of things like the GPS, camera, push notifications, and offline storage to streamline tasks for your team members in the field (when they’re in the trailer or off-location, for safety’s sake, of course).

KPA is Up to the Challenge

For E&P professionals, KPA offers compliance software and expertise suited for any situation. Manage your safety program in an all-in-one system designed to engage your employees, instill a culture of safety, and enable regulatory compliance. Safety maintenance within the energy industry can often result in massive headaches. At KPA, we are committed to helping you take some of the pressure off with our easy, intuitive training and tracking tools.

Learn more about KPA EHS Software >>