So, you’ve determined who’s on your Hazard Communication team and have a solid understanding of OSHA’s standard. Now it’s time to get your plan on paper and create your facility’s Hazard Communication Written Program.

Paragraph (e) of OSHA’s Hazard Communication Standard requires employers to prepare and implement a written hazard communication program. This helps ensure compliance with the standard is done in a systematic way, and that all elements are coordinated.

The goals of this written program are to document how your organization plans to ensure that employees are fully educated on the hazard communication process and the specific chemical products that they work with or around.

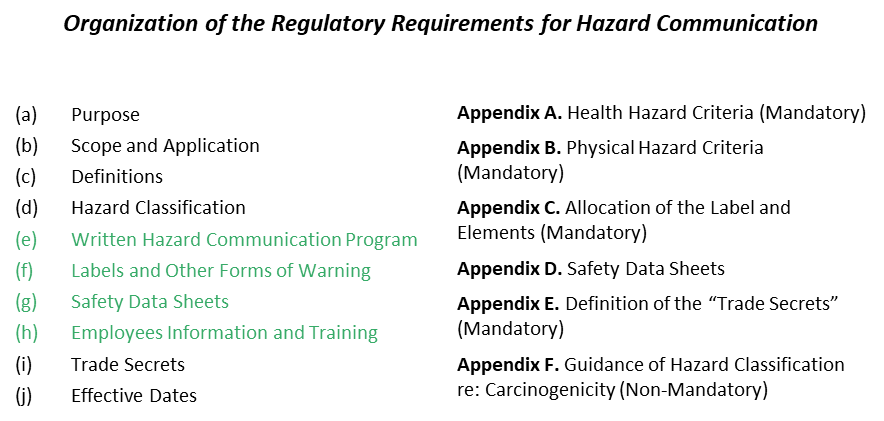

This plan must describe how you’ll address the requirements of these paragraphs from OSHA’s Hazard Communication Standard:

(f) Labels and Other Forms of Warning;

(g) Safety Data Sheets; and

(h) Employee Information and Training.

The written program must list all the chemicals present in the workplace, designate who is responsible for the various aspects of the program, and specify where written materials will be made available to workers.

The hazard communication process includes:

- Chemical labeling, including pictograms.

- How to read safety data sheets (SDSs).

- How to readily obtain SDSs in the event of a chemical exposure incident.

Common Sections in Your Written Hazard Communication Program

Roles and Responsibilities:

Determine who’s responsible for both the initial and ongoing activities needed for compliance. We’ve got some background for you here >>

Chemical Inventory:

Collect a list of all the chemicals present at your facility (more info later in the article).

GHS-Compliant Container Labeling:

A statement of how your organization will ensure containers will have GHS-compliant label prominently displayed

Safety Data Sheets (SDSs):

The who, what, where, and when details for how you’re managing your SDS library.

Training Requirements:

How you’ll be training your employees on your HazCom program.

Contractor Requirements:

What requirements will contractors working inside your facility need to follow?

Non-Routine Tasks:

What requirements will employees need to follow when working on non-routine tasks involving chemicals?

Documentation:

This section will contain things like your chemical inventory, the location of the your SDS inventory, employee training records, and contractor/subcontractor notifications.

How to Develop Your Chemical Inventory

Conduct a workplace survey to record all hazardous chemicals present. Identify all chemicals by reading the labels provided by the manufacturer (product identifiers include product name, product number, and the product’s hazards). Note the location(s) of the product(s) and where they are used.

Employers are required to have safety data sheets (or SDSs for short) for all hazardous chemicals they use. So, once you’ve compiled a complete list of the chemicals, determine if you have SDSs for all of them. If any are missing, contact the supplier and request one. Also, make sure purchasing procedures are in place to confirm receipt of SDSs in real-time before using any new chemical.

How KPA Helps Strengthen Your Hazard Communication Program

KPA is here to help you maintain a comprehensive Hazard Communication program.

HazCom Written Program

KPA’s expert EHS consultants will help you develop a written program that is tailored to your business. It will include everything OSHA looks for including:

- A list of all the chemicals present in your workplace

- How and where employees can access Safety Data Sheets

- Identify the individual designated as responsible for the oversight of your program

Hazard Communication Awareness Training

KPA also provides online and on-site Hazard Communication training. Courses for both employees and managers cover how information about hazardous materials is communicated in the workplace. They also include information about how to read hazard labels and safety data sheets as well as the importance of the written program and training.

SDS Management

Ensuring your employees have quick and easy access to Safety Data Sheets may be the most important component of your Hazard Communication program. With KPA EHS you have access to a database of over 70 million datasheets. You can create your own SDS folders and custom SDS library with an easy to search interface. You’ll also have offline access and hardcopies to ensure all your staff can easily find SDSs. Finally, you can print pre-populated secondary container labels for GHS compliance.