It can prevent workplace accidents and injuries, minimize the spread of disease, and even help you stay alive during a zombie outbreak. I’m referring to the simple, time-tested hazard prevention strategy known as the hierarchy of controls.

The hierarchy of controls is fundamental to workplace safety. It’s at the core of environment, health, and safety programs used by companies of all kinds, sizes, and industries.

Many government agencies and institutions that develop, monitor, and enforce workplace safety guidelines and standards also consider the hierarchy of controls a best practice—if not the best practice—for keeping people safe. From the Occupational Safety and Health Administration (OSHA) to the National Fire Protection Association (NFPA) to the National Safety Council (NSC), numerous organizations recommend that employers use the system when addressing workplace health and safety challenges.

The reason the hierarchy of controls is so popular is because it works. The system has saved countless lives and incalculable sums of money. It can be used to eliminate or minimize practically any kind of hazard.

Falls, chemical spills, vehicle collisions, exposure to toxic air pollutants, pandemics—you name it. Whatever risk you and your workers face, the hierarchy of controls can help you manage it.

Here’s everything you need to know about the hierarchy of controls—what it is, where it came from, and how to use it to prevent injuries, illnesses, and losses.

What Is the Hierarchy of Controls?

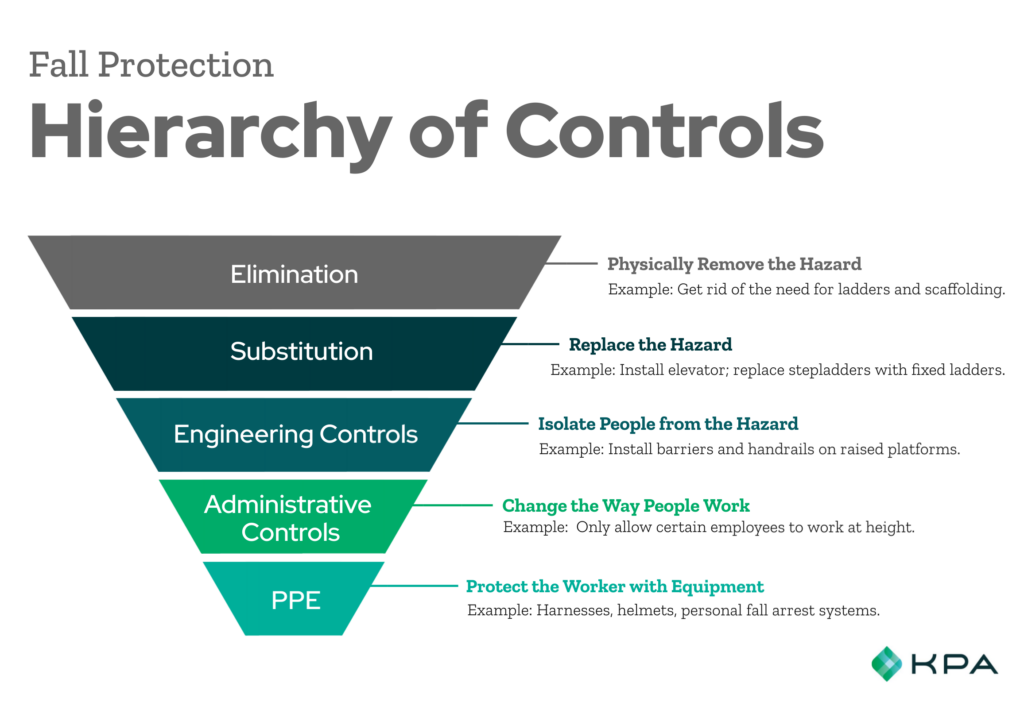

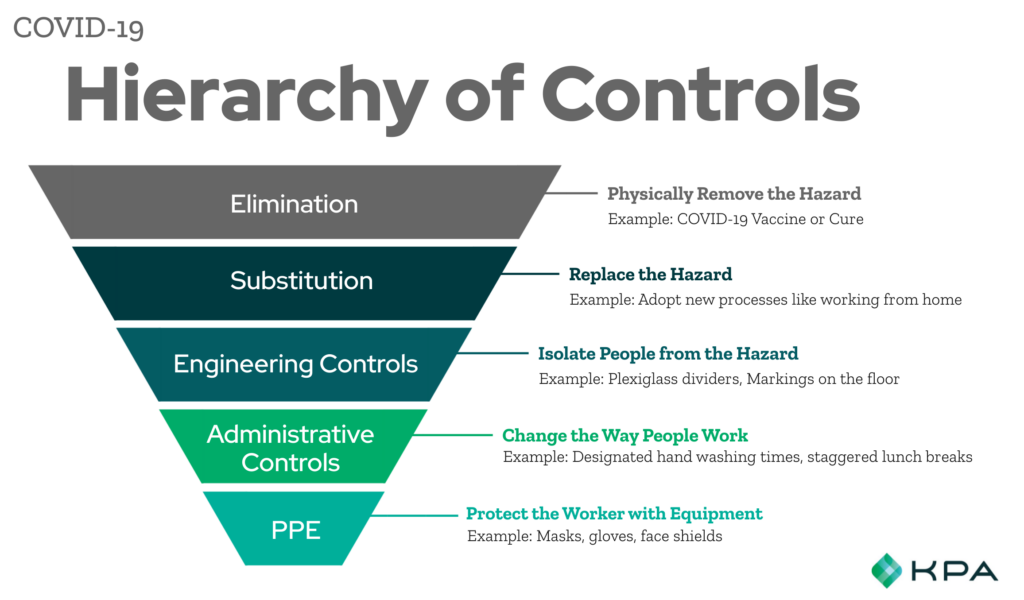

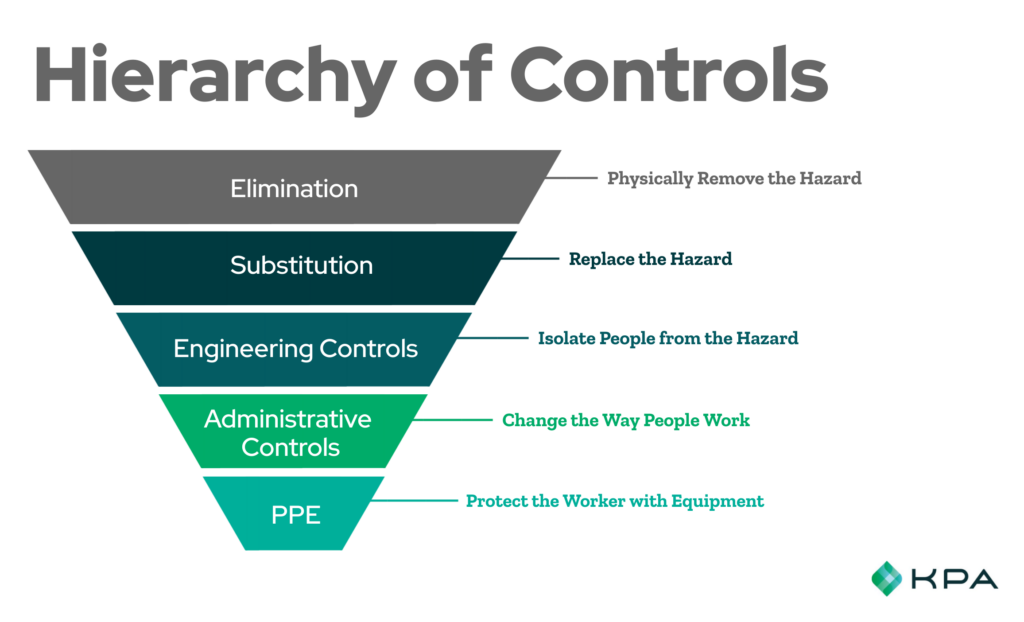

The hierarchy of controls is an approach to environmental safety (the environment in this case being a workplace) that structures protective measures into 5 stages, in order of most to least effective:

Think of these stages as lines of defense.

Elimination is the best possible defense. When you eliminate a hazard, you eradicate it or remove it from the environment where it can affect people. Curing a disease or finding a way for employees to do their work without leaving ground level would be examples of elimination.

Substitution is the second-best defense. It means replacing the hazardous thing or way of operating with something else—something non-hazardous or less hazardous. Maybe you replace a piece of cutting equipment with one that has fewer exposed sharp edges, for instance, or switch from a hazardous cleaning chemical to one that doesn’t produce toxic fumes.

Engineering controls are the next line of defense. When you engineer a solution to a hazard, you physically separate people from the hazard. Examples of engineering controls include guardrails, partitions, sound dampening materials, automated machines, and so forth.

Administrative controls aren’t as effective as engineering controls, but can still keep people safe. The idea here is to change the way people work—for instance, through rules and policies (e.g. “employees must wash their hands every 90 minutes”) or signage (“do not enter”).

Personal protective equipment (PPE) is the last line of defense. If you can’t get rid of the problem, swap it for something else, or engineer or govern it away, the only option left is to provide people with equipment such as helmets, goggles, gloves, boots, respirators, and hazmat suits.

Want some examples?

Here’s how you can apply this approach to different safety topics.

Where Did the Hierarchy of Controls Come From?

The hierarchy of controls has informed decades of workplace safety laws and practices. In fact, the concept predates the Occupational Safety and Health Act (OSH Act) of 1970, which created OSHA and the National Institute for Occupational Safety and Health (NIOSH).

It was the NSC, the leading occupational safety advocacy organization in the US, that first described the hierarchy of controls in the 1950s (although the idea of taking steps to prevent occupational injuries existed long before then). The NSC used the concept to demonstrate that occupational safety hazards could be controlled, and that certain control measures were more effective than others. Those early conversations ultimately helped shape the OSH Act, OSHA, and NIOSH.

In the decades since, the hierarchy of controls has remained central to workplace safety laws, regulatory guidance, and industry recommendations:

- NIOSH recognizes the hierarchy of controls as an important means of protecting workers, and includes it as a strategy in the national Prevention through Design initiative.

- OSHA mentions it in many recommended practices, guides (PDF), and resources.

- The NFPA has made the hierarchy of controls a central tenet of 70E, Standard for Electrical Safety in the Workplace.

- The NSC continues to highlight the hierarchy of controls in informational articles as well as tools for members.

The bottom line is that the hierarchy of controls is inextricably linked to workplace safety. It’s not only the why of safety—the very idea that employers can protect workers and control risks proactively rather than simply letting incidents happen—but also a template for how to minimize risks and prevent incidents.

How to Use the Hierarchy of Controls

The basic outline for using the hierarchy of controls is self-evident:

- Eliminate the hazard. If that’s not possible…

- Find a safe or less hazardous substitute.If that’s not possible…

- Engineer a solution to the problem.If that’s not possible…

- Use administrative means to keep people safe.And if that’s not possible…

- The only solution you have left is to provide workers with PPE and ensure they wear it properly for as long as they’re exposed to the hazard.

Determining how to design and implement these controls in your workplace takes careful planning, consideration, and investment. There is no one-size-fits-all hierarchy of controls available out of the box. You may be able to find pre-built solutions for some controls but will need to customize other solutions or develop them from scratch.

Here are a few tips for building and using the hierarchy of controls effectively:

- Conduct a safety audit first. You can’t control what you don’t know. Begin by auditing your organization and facilities to identify all existing and potential hazards.

- Start at the top. Always use the most effective control you can. If you can eliminate a hazard, you have a responsibility to do so.

- Use every available control. Do everything you can to keep your people safe. Don’t rely on just one control or one level of the hierarchy. You will almost certainly need to implement multiple solutions at different levels simultaneously—e.g. PPE, machine guards, policies, and safe working practices all at the same time.

- Know your biggest risk areas. Some injuries and illnesses are more common and/or critical than others. Implement controls for your most likely, serious, and costly hazards before addressing less urgent matters.

- Don’t neglect training. Your workers need to understand the importance of safety and know how to do their jobs safely—or else the hierarchy of controls makes no difference.

- Document everything. The only way you can prove (for instance, during an OSHA inspection) that you followed the hierarchy of controls is to keep complete, accurate, and up-to-date records of your safety program.

Keep your workforce safe and eliminate your risks with KPA. We have the software tools, award-winning training solutions, and expert consultants you need to implement the hierarchy of controls and optimize your workplace safety program. Learn more.