Let’s talk fire extinguishers. Have you inspected yours lately? Are they fully charged, strategically located, accessible, and ready for use? Or, are they covered with dust and hidden in a corner where they create a false sense of security? Do you employees know how to use them? Before OSHA comes in to ask, it’s best if we answer these questions ourselves.

Do you know everything you need to know about the most frequently cited Occupational Safety and Health Administration standards? In this series, we’re exploring the most common OSHA violations, one by one. Keep reading to learn how to avoid an electrical violation and protect your portable fire extinguisher citations.

OSHA’s Portable Fire Extinguisher Standard: What It Is

OSHA definition:

“The employer shall provide portable fire extinguishers and shall mount, locate and identify them so that they are readily accessible to employees without subjecting the employees to possible injury. Only approved portable fire extinguishers shall be used to meet the requirements of this section. The employer shall assure that portable fire extinguishers are maintained in a fully charged and operable condition and kept in their designated places at all times except during use.” (Source)

Simple definition:

Fire extinguishers must be kept accessible and functional to eliminate lost time when needed. They should also be the proper class of extinguisher based on the kinds of materials in your operation.

Like most aspects of emergency preparedness, fire extinguishers are tools companies hope never to use. Tools that go untouched for long periods can be prone to neglect, but giving your fire extinguishers the proper inspection and maintenance they require is essential. Fire extinguisher inspections are legally required to keep them ready for use if needed and ensure they can effectively extinguish fires. Remember, those fire extinguishers are your first line of defense against fire emergencies.

While we hope that fire extinguishers never have to be used, they still need to be inspected and maintained to ensure they are working properly in case an emergency occurs.

Why Fire Extinguisher Violations Happen

OSHA fire extinguisher violations usually happen for a host of reasons.

- Improper fire extinguishers are supplied, or they’re not distributed across your facility adequately. Remember, not all fire extinguishers are created equally.

- Fire extinguishers aren’t maintained. A dusty, hidden extinguisher isn’t going to help you respond well to an emergency.

- Lack of fire extinguisher inspection records. The same goes for employee training on how to use a fire extinguisher effectively during emergencies.

What You Stand to Lose When Fire Extinguisher Violations Happen

Direct costs: OSHA penalties can exceed $16,000 per violation—and as much per day for every day the issue hasn’t been fixed by OSHA’s deadline. The fine for a willful or repeated violation can be 10 times as much.

Indirect costs:

- workers’ compensation claims from people who have experienced injuries and illnesses from a fire

- lost productivity during and after a fire

- lowered workforce morale due to fear and uncertainty around risk areas

- hours of labor spent identifying and fixing issues

- expenses of cleaning and replacing equipment that’s out-of-date, damaged or broken

- legal and compliance fees

- negative publicity and reputational damage

Signs You’re at Risk of a Fire Extinguisher OSHA Violation

This can range from paper and wood products to combustible metals like magnesium and aluminum or flammable liquids like oil, gasoline, or paint.

Think motors, heaters, office machines…things that can spark and start electrical fires.

If it’s been over a year since you underwent a maintenance inspection or a month since you’ve done a visual one, you could be in trouble. This can put lives and property at risk.

Anyone who could be exposed to a fire hazard should be trained and up-to-date with how to operate a fire extinguisher.

How to Avoid an OSHA Fire Extinguisher Violation: Your Prevention Checklist

Do you have the proper Class of extinguisher for the materials most likely to burn in your operation? Ensure you have the right kind of fire extinguisher for these situations.

Here’s a list of the different classes of fires and the recommended fire extinguishers used for each.

The correlation is very straightforward:

Class A fires require Class A extinguishers,

Class B fires require Class B extinguishers, etc.

Class A Fires:

Involve ordinary combustibles such as paper, plastic, rags, and wood.

Class B Fires:

Involve flammable liquids such as oil, grease, gasoline, and paint.

Class C Fires:

Involve electrical equipment such as motors, heaters, and office machines.

Class D Fires:

Involve combustible metals such as magnesium, aluminum, sodium, and potassium.

Class K Fires:

Involve combustible cooking fluids such as oils and fats.

Some types have multiple ratings, which makes them usable for different classes of fires. But remember, if you do not know what kind of materials are burning or if you do not have the proper class of extinguisher, do not try to fight the fire; evacuate immediately.

How often should I check and maintain fire extinguishers?

OSHA guidelines recommend that fire extinguishers be inspected monthly. This includes checking for accessibility, ensuring the pressure gauge is in the green zone, and verifying that the nozzle is free from obstructions. In addition to monthly checks, an annual professional maintenance inspection is required to ensure the fire extinguisher is properly working. Always follow the manufacturer’s recommendations for maintenance frequency.

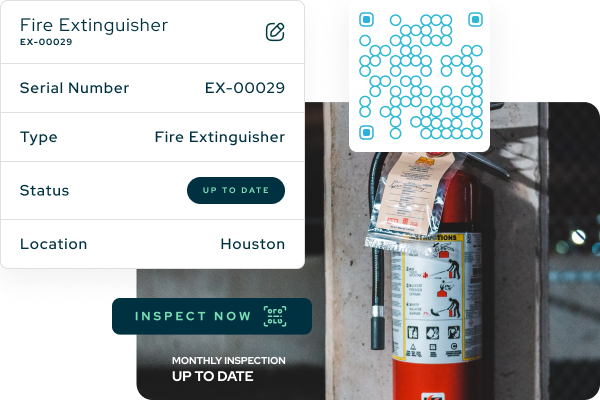

Inspect your extinguishers monthly to ensure they are charged and in ready-to-use condition. To keep your fire extinguishers operational and legal, you should inspect them monthly and annually.

Annual Fire Extinguisher Inspection

OSHA (29 CFR 1910.157(e)(3) also requires an annual fire extinguisher maintenance inspection which a professional fire extinguisher company must perform. Depending on the type of fire extinguisher, it may also require a 5-year, 6-year, or 12-year inspection or replacement.

Monthly Fire Extinguisher Inspection

A monthly fire extinguisher inspection is a quick visual inspection done by an employee as required by OSHA (29 CFR 1910.157(e)(2)). Areas include inspecting the handle, pull pin, gauge, seal, labels, mounting bracket, and more. Download the monthly inspection checklist to get started.

Other maintenance and inspection requirements are needed based on the type of extinguisher. Your manufacturer owner’s manual will have this info. Building reminders into your calendar is an easy way not to forget to complete the task.

If staff will be expected to use fire extinguishers in an emergency, be sure that they have received training on how to use them correctly. It’s one of the first things OSHA Inspectors want to review when they come on-site. Be ready for the ask.

Check out a sample fire extinguisher safety inspection training from KPA.

What is the proper way to use a fire extinguisher?

To properly use a fire extinguisher, remember the acronym PASS:

- **P**ull the pin.

- **A**im the nozzle at the base of the fire.

- **S**queeze the handle.

- **S**weep the nozzle from side to side.

Always ensure you are standing a safe distance away and approach only if the fire is small enough to put out a small fire. If the fire spreads or becomes uncontrollable, evacuate immediately and call the fire department.

You Don’t Have to Manage Your OSHA Requirements Alone

Have questions? Looking for more detailed OSHA compliance guidance? KPA is here to help.

To truly protect your workforce and bottom line, you’ll need in-depth information—and not just about OSHA’s top 10, but every potential hazard that exists in your organization. You’ll also need to conduct a thorough evaluation of your facilities to identify current gaps and risk areas.

KPA’s unique combination of software, training, and consulting services can provide the coverage your people and your organization need.

Related Content

Explore more comprehensive articles, specialized guides, and insightful interviews selected, offering fresh insights, data-driven analysis, and expert perspectives.