When dealerships think about chemical inventories, they often imagine a binder full of Safety Data Sheets (SDS) gathering dust on a shelf. But an effective chemical inventory program is far more dynamic – it’s a living system that integrates with your written programs and policies while actively protecting your employees and business.

Beyond the Binder: Why Chemical Inventories Matter

Your chemical inventory isn’t just a compliance checkbox. Safety Data Sheets contain critical information that impacts multiple aspects of your safety program, from the personal protective equipment (PPE) your technicians need to wear, to the ventilation requirements in your service bays, to how you’d respond in an emergency. But this information only becomes valuable when it’s properly assessed and integrated into your daily operations.

Making Smart Chemical Choices: A Real-World Example

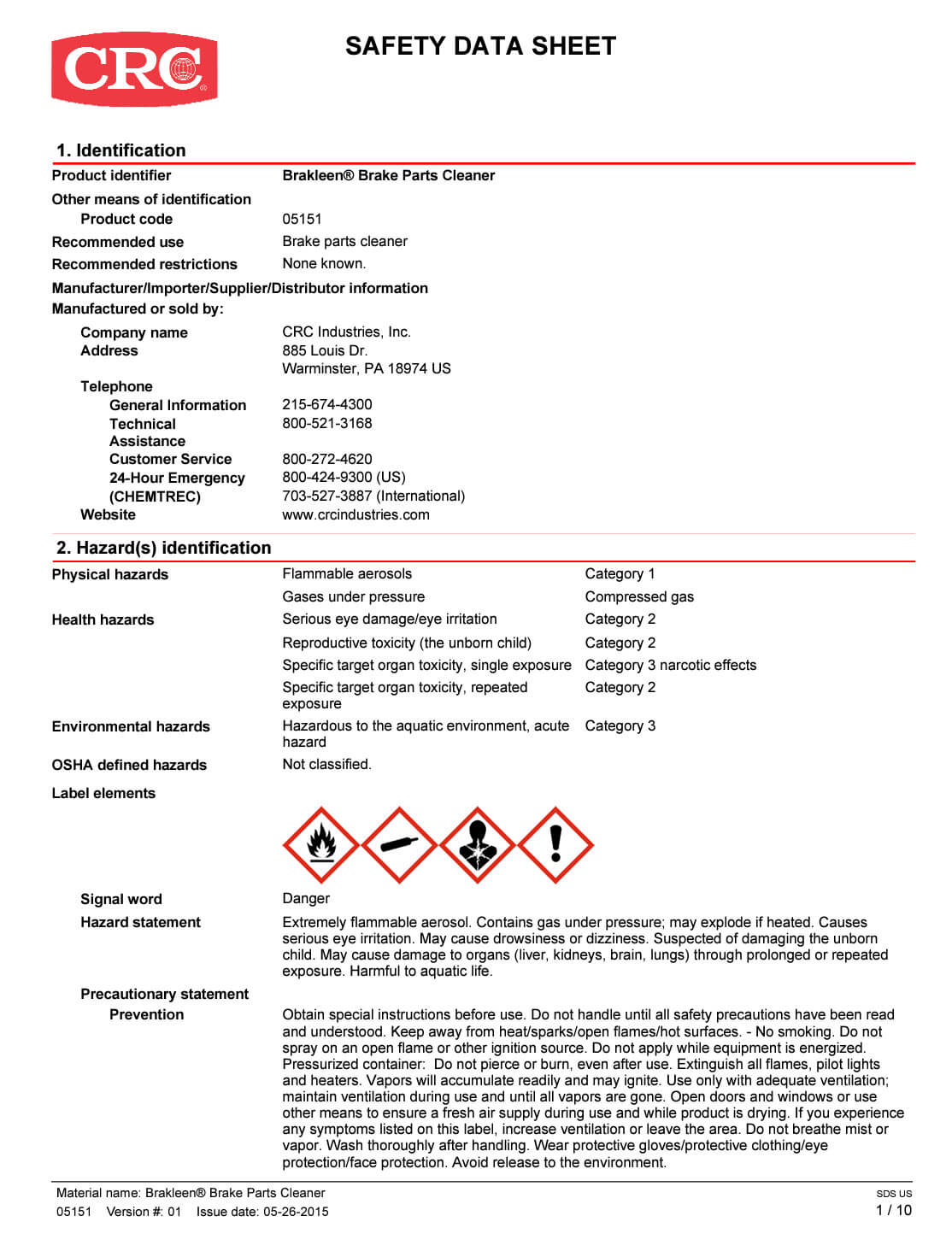

Let’s look at a common example in dealerships: brake cleaner. If you check the SDS for a chlorinated brake cleaner, you might find it requires air monitoring for exposure, respirator use, and specialized gloves like neoprene instead of standard nitrile gloves. When dealerships see these requirements, their first reaction is often, “We don’t want our techs dealing with all that extra PPE!”

This is exactly where a thoughtful chemical inventory program shows its value. Instead of just accepting these requirements, you can explore less hazardous alternatives that are just as effective but don’t put such a burden on your employees. This kind of assessment and substitution process is a key part of a mature chemical safety program. Remember, price should not be the only factor when purchasing products for your workplace, factoring in the safer product to protect your most important asset in your employees should always be a part of the decision making process.

Dealer's Pocket Guide to Hazard Communication

In this pocket guide, we have broken down Hazard Communications into 6 easy steps for you.

Emergency Planning and Storage Requirements

Your chemical inventory directly impacts your emergency preparedness. Different chemicals require different storage conditions and emergency response equipment. For instance:

- Some chemicals must be stored in specialized flammables cabinets

- Certain chemicals may require alternative fire suppression instead of standard ABC extinguishers

- Storage locations need to be properly chosen to prevent dangerous chemical interactions

Beyond Basic Compliance: A Comprehensive Approach

To build an effective chemical inventory program, you need to thoroughly review each SDS for:

- Hazards of the chemical

- First aid procedures

- Specific PPE requirements

- Ventilation needs

- Appropriate firefighting measures

This information should then feed into your written safety programs, emergency action plans, and training requirements. It’s an ongoing process that requires regular updates and assessments as new products enter your facility or better alternatives become available.

Building a Safer Workplace

A well-managed chemical inventory program does more than just meet regulatory requirements – it helps create a safer workplace while potentially reducing costs through smart product selection and streamlined PPE programs. The key is to treat your chemical inventory as an active safety management tool rather than just a documentation requirement.

Remember: your chemical inventory program isn’t static. As you add new products or find better alternatives, your programs and policies should evolve to reflect these changes. This dynamic approach helps ensure your employees stay safe while keeping your dealership compliant.

Complete Dealership Compliance from KPA

Keep your dealership safe from environmental factors that impact your workers’ and customers’ safety. KPA helps auto dealers maintain cultures of safety, streamline operations, and manage risk through a robust set of tools that includes a combination of consulting, training, and regulatory content.

Next Week, Let’s Look at Training and Certification

Join us as we break down the essential steps every dealership must take to build and maintain a successful safety program. If you haven’t already, subscribe to our blog for weekly installments of the 10 steps to complete compliance.

Follow a 10-step journey to compliance.

Move your mouse over each step to learn more about each step.

Related Content

Explore more comprehensive articles, specialized guides, and insightful interviews selected, offering fresh insights, data-driven analysis, and expert perspectives.