Learn to prevent electrical accidents in the workplace with these expert safety tips for your next Electrical Safety toolbox talk. In this 5-minute toolbox talk overview, you’ll learn how to identify common electrical hazards, give employees training on the latest safety guidelines, and improve your electrical safety program to reduce the risk of injury or death.

Construction workers do far more than swing a hammer or drive a nail. They’re the ones that make a company successful. And when an accident occurs on their watch, the consequences can devastate everyone involved. You know this better than anyone else – and so does your insurance company.

Pop Quiz: Would your premiums go up or down if an employee gets hurt or even killed on the job?

That’s why it’s so important that your workers are properly trained. This includes everything from knowing how to use certain tools and machinery to proper ladder safety procedures.

This also means ensuring they know what they’re doing at all times – even if it’s just walking across the street or driving home after work. After all, it only takes one bad move for something terrible to happen.

Here are some simple yet effective tips that can help you avoid injuries from exposure to electricity.

Don’t Forget The Go-To for Toolbox Talk Guidelines

Workplace safety is important at all times, but even more so when you are working with electricity. That’s why all electricians need to follow the OSHA rules and best practices outlined in the 29 CFR 1910 standard.

These standards cover everything from training requirements to equipment maintenance. They also provide extensive information on how to make sure your employees are using the proper equipment and working as safely as possible.

The standard also contains requirements for the installation of electrical equipment, and safety requirements for tools, materials, and construction practices. The 1926 standard applies to electrical installations in all areas of construction except those covered by 29 CFR 1910. The standard contains requirements for establishing electrical safety programs, electrical equipment, work practices and procedures, grounding and bonding of electrical systems, and temporary wiring involved in construction work.

Electrical Safety Toolbox Talks Made Easy

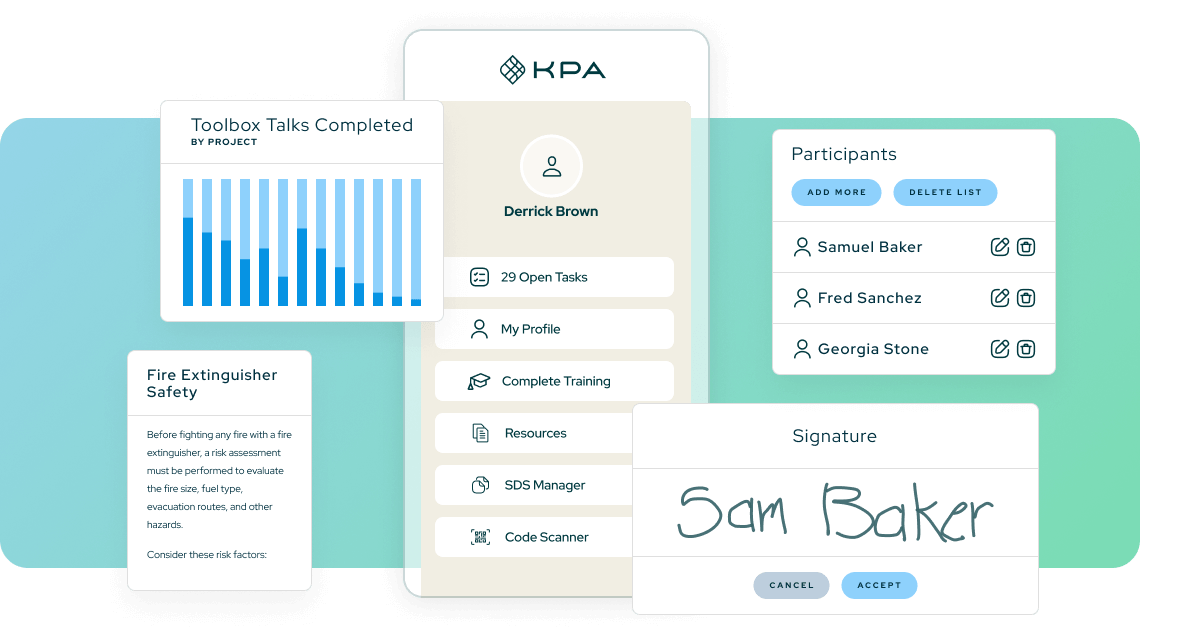

Ready to make compliance convenient? KPA Flex’s prebuilt Toolbox Talk Software keeps safety at the forefront of your team’s daily routine, ensuring a proactive approach to incident prevention and compliance.

Safety Software for Electrical Contractors

Streamlined safety and compliance results in fewer shocks, burns, and other safety incidents. KPA Flex is the only start-to-finish safety and compliance management software designed with electrical construction contractors in mind.

Related Content

Explore more comprehensive articles, specialized guides, and insightful interviews selected, offering fresh insights, data-driven analysis, and expert perspectives.