Anyone working with petroleum or other chemicals has the specter of spills looming around every corner. And your approach to spill response brings up so many questions.

- Do we have to report every spill? Even if it’s small or doesn’t go near a drain?

- Who is responsible if a third-party vendor causes a hazardous material spill that reaches a storm drain?

- With frequent employee turnover and increased use of hazardous materials, are you sure that your employees will notify the proper authority in the case of a spill?

We’re here to help banish the specters. We’ve collected some examples and best practices you can learn from to reduce your risk from pollution fines.

The Environmental Protection Agency (EPA) provides each region a 24-hour number to call in a release or environmental emergency. So, what’s an environmental emergency? It’s “a sudden threat to the public health or the well-being of the environment.” This includes oil or chemical spills, radiological or biological discharges, or accidents that can cause a release or even a potential release of pollutants into storm drains, wetlands, public areas, or the air.

Spill Response and Storm Drains

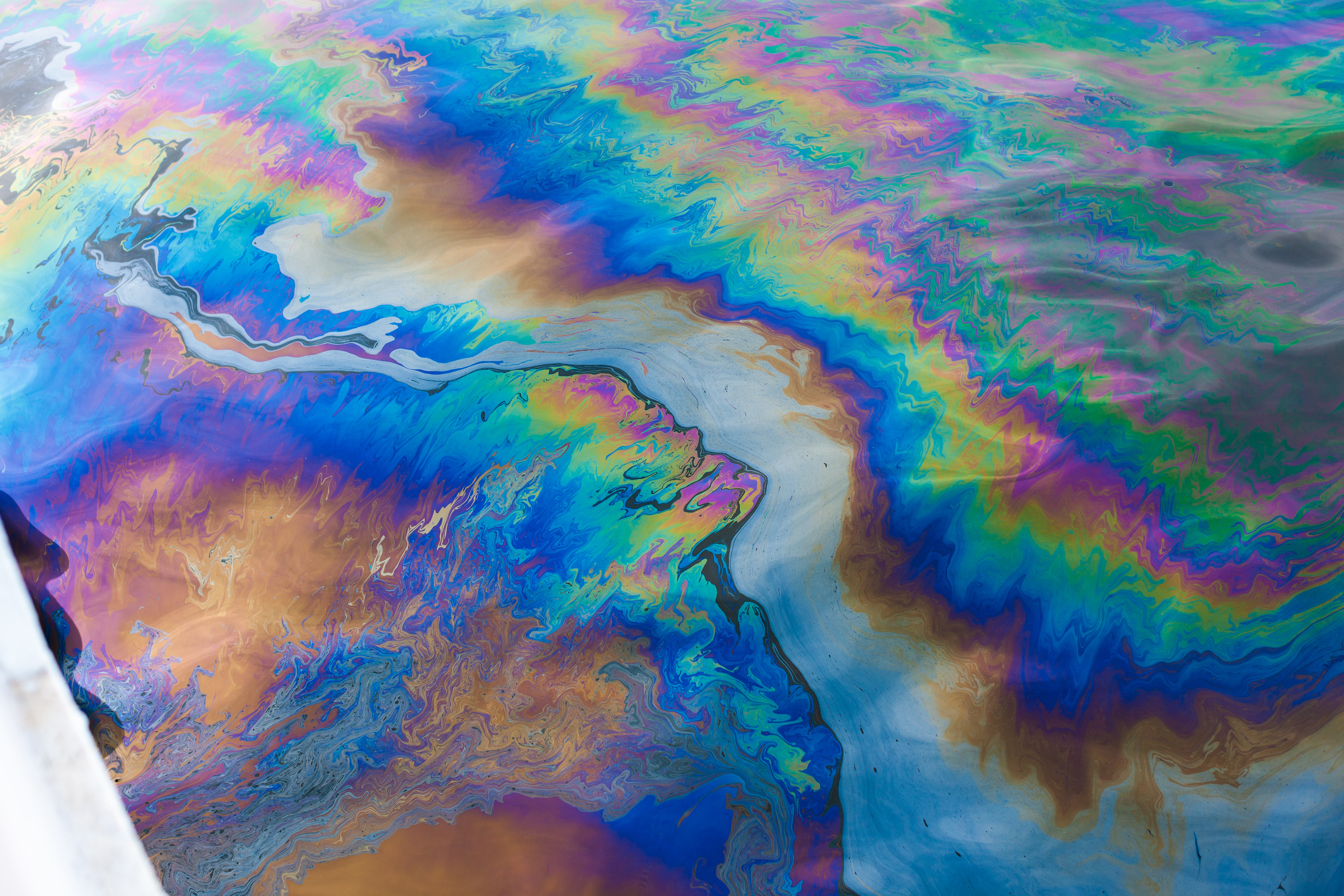

Nothing should enter a storm drain that could cause a sheen (iridescent appearance) on water. This includes oils and some cleaning products, even those designated as “biodegradable.” The EPA states that for one ounce of biodegradable detergent to be safe for fish, it needs to be diluted by almost 20,000 ounces (over 150 gallons) of water.

Essentially, the only thing that should enter a storm drain is natural rainwater runoff.

If you do have a spill, it’s essential to clean it up properly. Consider this scenario: A recent spill was poorly cleaned and happened to dry on the property. A rain or washing can transfer residuals down storm drains. If discovered by water authorities, this could subject your facility to reporting requirements and potential fines.

This brings us to our next topic…

Spill Response Fines

Under the Clean Water Act, each state must enforce federal standards when it comes to public waterways. Individual states, counties, or governing agencies can have more stringent water regulations, including what a reportable quantity is and specific cleanup procedures. Owners and/or operators may be subjected to fines determined by their local regulators. They can be subjected to a civil penalty of up to $57,000 per day of violation or an amount per barrel of oil or unit of reportable quantity of a hazardous substance.

Learn From These Examples: Reduce Your Exposure from Chemical Spills

Know the locations of all of your drains and where they lead.

Recently, an auto dealer received a call from their local water district informing them that the water being discharged into their storm drain system was “grey” or sludgy. This alerted the facility to look at all of their drains on site. The only drain that had continuous water flowing into it was one that they had thought led to an oil/water separator for their car wash area, which only used biodegradable soap. After careful investigation, they discovered that the car wash drain was not connected to the nearby oil/water separator but discharged directly to their storm drain system.

Accidents happen. But following best practices can keep fines at bay.

A facility under construction had an employee use a forklift to move a used oil filter container to the front of the facility for pickup by their waste hauler. The forklift driver hit a bump in the parking lot during the transfer, resulting in the filter container toppling over. Unfortunately, the container had a few gallons of residual oil from its filters, and the accident happened right over a storm drain. The fire department witnessed the event and was able to begin remediation right away with the help of the operator’s spill kit. But the facility didn’t have a formal procedure for spill prevention and response, and they were assessed a remediation fee.

Third-party vendors can do a lot of damage at your facility without your knowledge.

Does that mean it’s your responsibility to fix their problems?

A transporter truck was dropping off cars and hit a fixed object in the parking lot, causing a puncture in the truck’s diesel tank. The leaking diesel fuel ended up draining directly into a storm drain.

The trucking company immediately called their corporate office to deploy a hazardous material spill response crew. And the facility operator contacted the property owner to inform them of the situation and called their local non-emergency dispatch numbers for fire and police.

The cleanup procedure went smoothly. They recovered 30 gallons of diesel fuel from the pavement and remediated the gallon of fuel that made its way down the storm drain.

Within a few days, the local Fire Marshall and local inspectors visited the facility, examining the diesel spill and inspecting the entire facility looking for additional problems. The regulators determined that the trucking company had not used the proper channels for reporting the spill. But since the spill occurred on the facility’s property, the owner/operator was responsible for reporting the spill to the local EPA office. The facility operator had contacted the EPA, but not immediately, to the federal inspector’s displeasure. The EPA launched an investigation into potential contamination of downstream waterways and were eventually satisfied with the cleanup process.

Spill Prevention Best Practices

- Cover storm drains when transferring any materials over them.

- Seal containers before moving them.

- Maintain well-stocked spill kits, including absorbent booms, socks, or mats.

- Check with your local Hazardous Materials division or waste hauler to see if they have a remediation crew before you have an accident.

- Know your reportable quantities. The Reportable Quantity (RQ) for the release of oil into the environment, excluding navigable waters, is an amount of 25 gallons or more. The RQ for the discharge of oil into or upon navigable waters is an amount which causes a visible film or sheen upon the surface of the water.

- If you have a spill, make sure to call the EPA. They will dispatch you to the regional authorities who govern your waterways. This could be under the jurisdiction of the Coast Guard, local LEPC representative, or fire department.

- Post non-emergency, after hours, or dispatch numbers to your local police and fire departments. In some locations, 911 dispatchers deploy emergency assistance from areas that are not close by, resulting in the delay of hazardous material spill responders.

- Check your material Safety Data Sheets for emergency spill contact information.

Scared straight yet? Experiencing nightmares featuring oily sheens? KPA’s here to help.

KPA offers environmental risk management services to assist you in managing chemicals and hazardous waste at your facilities. We help you document procedural compliance and provide guidance on minimizing waste generation and appropriately managing and disposing of wastes. Our compliance inspections, plan development, and permitting assistance will help you resolve your environmental compliance challenges.

Spill Prevention, Control, and Countermeasure Plans

If your facility handles oil, including storing, using, and transferring oil, and there is a reasonable expectation that an oil spill may reach navigable waters of the United States, you may need a Spill Prevention Control and Countermeasure (SPCC) Plan per the SPCC Rule.

Stormwater Pollution Prevention Plans

Stormwater pollution permit requirements are complex as each site may require permits at the local municipality, state, and federal levels. While requirements may vary, your Stormwater Pollution Prevention Plans require analysis of potential pollutants, the actions taken to mitigate the chance of pollutants spilling out of the site, and documentation on your inspection program to track the effectiveness.

KPA can design site-specific plans for your company in compliance with local, state, and federal requirements. KPA assists in conducting the necessary stormwater sampling, analysis, and filing requirements.

Your local consultant can act as a liaison to local, state, and federal regulatory agencies. Plans are prepared by Qualified Industrial Stormwater Practitioners (QISP). KPA’s Facility Compliance Inspections and Loss Control Audit services assist clients with fulfilling required training and inspections.

Contact us to get started. And sleep easy knowing KPA has your back >>