Frequent employee engagement is the keystone to building a culture of safety in your organization. If you follow this blog, you’re *almost* sick of us talking about it.

You know you need to blend in-person conversations with online tools. And two tactics come up frequently as great ways to increase your in-person interactions – Safety Meetings and Toolbox Talks.

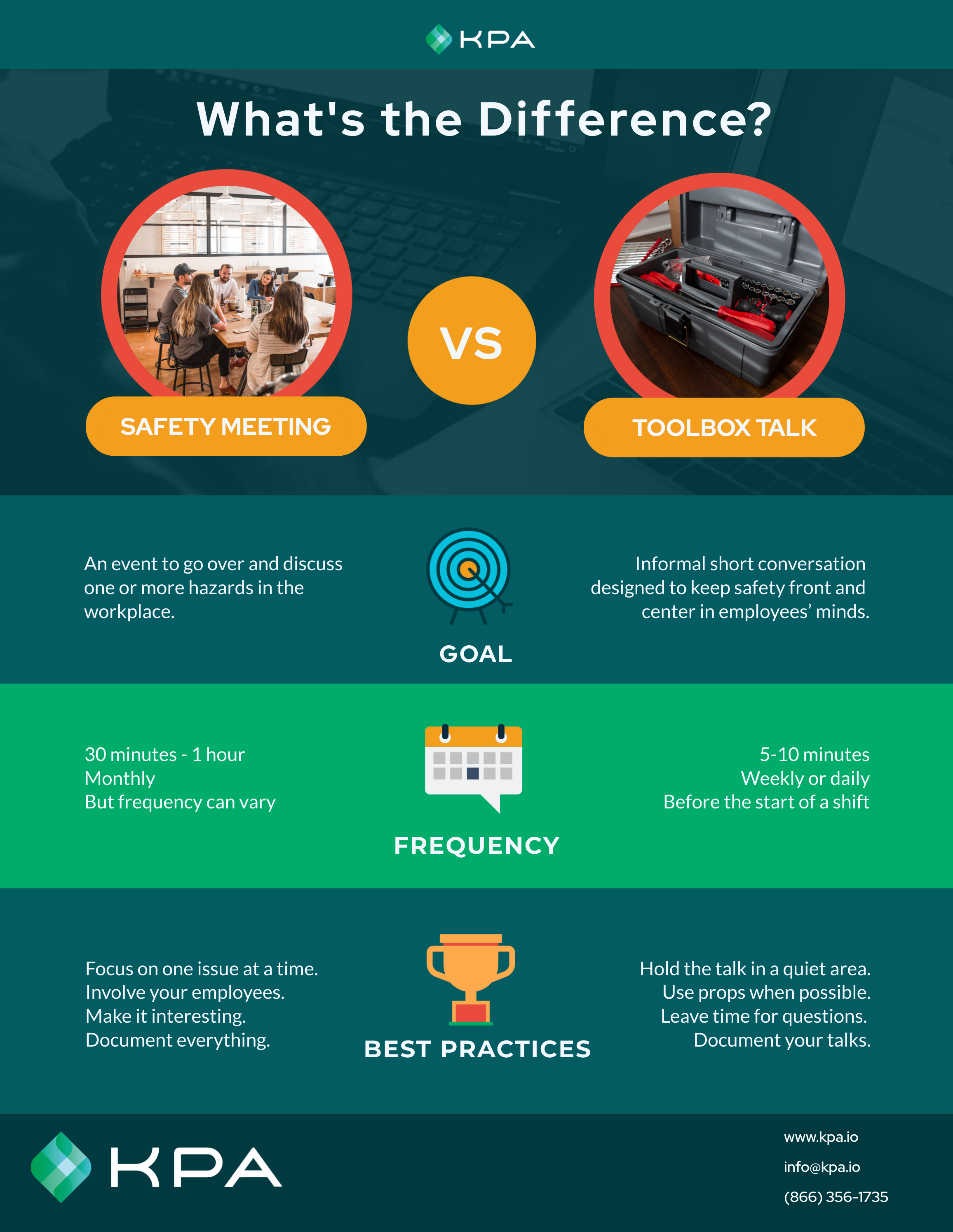

But do you know the difference between the two, and when to use each one for the best results? We’re here to break down the differences and give you some best practices on how to use each most effectively.

Ready? Here we go!

Toolbox Talks

Toolbox Talk Goals

- Informal short conversation designed to keep safety front and center in employees’ minds.

- Sometimes called tailgate talks or Safety Chats, they’e intended to supplement formal safety training.

- An effective way to refresh people’s knowledge, cover last-minute safety checks, and exchange experienced workers’ information.

Toolbox Talk Frequency

- Weekly or daily, before the start of a shift

Toolbox Talk Length

- 5-10 minutes

Toolbox Talk Best Practices

- Try to hold the toolbox talk in an area that is free of noise and other distractions.

- Use a prop when possible to help you keep people’s attention.

- Discussing ladder safety? Make sure you have one on hand to point out key things.

- Grab an unlabeled container you found on the job site. That’s a great way to reinforce your hazard communication requirements.

- Leave time for questions and make sure people feel comfortable asking them. You don’t want someone to get injured because they didn’t feel comfortable asking a “stupid” question.

- Document your talks. Make sure you’re recording the date, topic, trainer, and attendees to reinforce your commitment to safety to any regulators who come calling.

Toolbox Talk Topic Ideas

- Specific hazards that pertain to a project people are currently working on.

- A topic based on what supervisors are observing in the workplace.

Safety Meetings

Safety Meeting Goals

- Safety meetings are more formal than toolbox talks and typically longer. Think of it as a seminar or learning session rather than a quick huddle.

- These are events used to go over and discuss one or more hazards in the workplace. They may comprise several formats—such as interactive training, activities, and Q&A.

Safety Meeting Frequency

- Monthly, although the frequency can vary.

- If you’re seeing increased accident rates and your safety program isn’t performing well, you likely need to increase the frequency of your safety meetings. Program going smoothly? You might be able to spread them out more.

Safety Meeting Length

- 30 minutes – 1 hour

Safety Meeting Best Practices

Focus on one issue at a time.

The most effective safety meetings are the most simple and direct. Don’t try to educate your workforce on the entire safety program at once. Emphasize one important issue during every safety meeting.

Involve your employees.

Your workers aren’t just the audience for your safety meetings—they should also take part in making the meetings happen. Ask employees for topic suggestions. Collect questions before the meeting. Have a member of your team give a demonstration, tell a story, or lead a discussion. These practices will ensure the meetings are relevant and specific to the people they need to reach.

Make it interesting.

Safety meetings can and should be fun. Try out a variety of media and approaches. Why not have employees role-play or engage in a simulated safety scenario? Humor goes a long way as well, but be sure it’s appropriate to the topic, and use it to draw attention to your message rather than distract from it.

Document everything.

Make sure to record the relevant details of every safety meeting: when it happened, what it was about, who led it, which employees attended, and what activities attendees engaged in.

Safety Meeting Topic Ideas

Look at your safety program data to get ideas

“We had 11 falls last quarter. Let’s take a close look at our fall protection procedures and make sure everyone is doing their job safely.”

What’s happening in your environment

“With wildfire season right around the corner, it’s time to have a discussion about wildfire safety and smoke exposure. We’re going to watch a short video, go over what you need to know, break into groups for an activity, and then open the floor for questions.

What’s happening in your organization?

“Our team in Houston is showing better safety and compliance scores than the team here in San Diego. Let’s take a look at what they’re doing and find out how we can catch up.”

“As many of you know, we’re looking to recruit more forklift drivers. I wanted to use this opportunity to make sure our forklift training is top of mind, introduce you to some new procedures, and answer any questions you might have.”

“I’ve heard concerns from safety managers that they’re losing time running upstairs to their desks and grabbing paperwork whenever there’s an accident. Let’s review our current procedures, act out an accident, and find out if there’s any way we can simplify accident response.”

Remember, safety meetings and toolbox talks can’t turn things around by themselves.

Both of these are incredibly important to build employee engagement in your safety program. But, it’s important to optimize other pieces of your safety program, such as training and reporting, in tandem. That’s where KPA can help.

KPA’s combination of EHS software, expert consulting, and award-winning training makes it easy to unite your employees around your safety program and build a genuine safety culture in your workplace. We’ll help you plan, conduct, and document your safety meetings and toolbox talks. Use our flexible software to educate your employees on critical EHS topics, keep track of compliance, and much more.