Do you know everything you need to know about the most frequently cited Occupational Safety and Health Administration standards? In this series, we’re exploring the most common OSHA violations, one by one. Keep reading to learn about OSHA’s scaffolding standards.

The OSHA Standard For Electrical Systems

All electrical systems have the potential to cause harm. The Occupational Safety and Health Administration (OSHA) requires employers to keep their employees safe near all electrical hazards. Part of this requirement includes the safe examination, installation, and use of electrical equipment.

Qualified Individual:

A qualified person has been trained to avoid electrical hazards when working on or near exposed energized parts and is:

- Familiar with the safety-related work practices required in 29 CFR 1910.331-1910.335

- Able to distinguish exposed live parts of electrical equipment

- Knowledgeable of the skills and techniques used to determine the nominal voltages of exposed parts

Unqualified Individuals

An unqualified person is someone who has little or no training regarding electrical hazards. Even though unqualified persons may not be exposed to energized parts, make sure they’re trained and familiar with your electrical safety practices.

Whenever work needs to be done on or around an electrical system, make sure everyone in the facility understands OSHA’s safety guidelines. They also need to know where potential danger exists and how to avoid it.

Safety signs and labels throughout the facility are a great way to bring attention to any electrical hazards. Train your staff to make sure they understand how to stay safe when working with electrical systems.

OSHA has a helpful eTool: https://www.osha.gov/etools/subpart-s. The eTool shows employers all of the Subpart S installation requirements that apply based on the time period in which an installation was built or last modified.

Items that fall under OSHA’s 1910.303 Standard include…

- Wiring

- Labeling of Wires

- Splices

- Arcing Parts

- Markings

- Disconnecting Means and Circuits

- Working Clearances

What You Stand to Lose When Electrical Systems Violations Happen

Direct costs: OSHA penalties can exceed $15,000 per violation—and as much per day for every day the issue hasn’t been fixed by OSHA’s deadline. The fine for a willful or repeated violation can be 10 times as much.

- workers’ compensation claims from workers injured by falls or falling objects

- lost productivity during and after an incident

- costs of replacing any damaged scaffolds or equipment

- legal and compliance fees

- decreased morale

- negative publicity and reputational damage

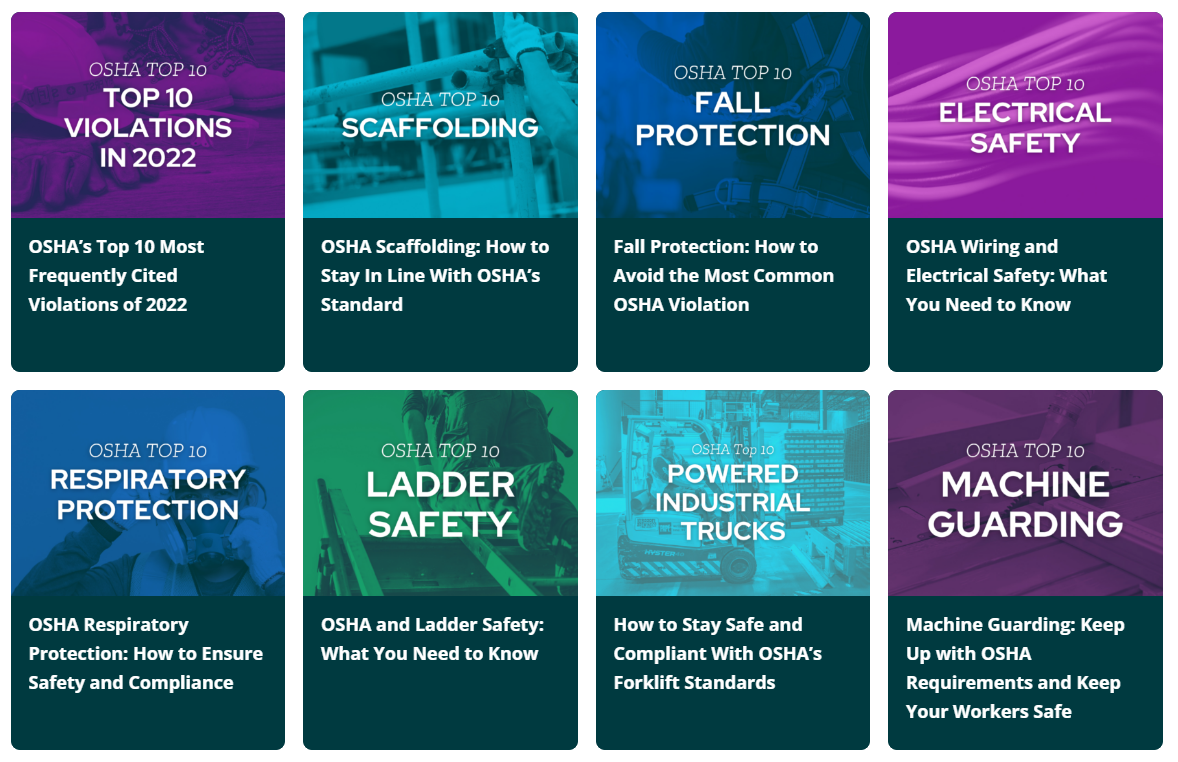

Read up on all of the top violations in the

OSHA Top 10 Resource Hub

Why Violations Happen

Violations can occur when wiring is not correctly labeled.

Labeling should include:

Inform others of where the electrical system being labeled is going. This helps when troubleshooting power outages, or surges, throughout the facility.

Knowing how old a general electrical system is will be helpful when planning upgrades.

Listing any warnings. For example, listing that the wiring’s not insulated against high heat can help ensure that a high heat-producing machine doesn’t get installed in the area.

Labeling whether a power source is going to a machine or area that is critical to the facility is a good practice. This will help ensure that maintenance staff take extra precautions before cutting the power.

Identifying how much electricity can travel through a particular electrical system before the fuse or other cutoff will occur is also important. This will help when adding additional machines or other things that will draw electricity.

Signs You’re at Risk

- Your organization performs work installing new electrical systems

- Your organization performs work updating existing electrical systems

- Your organization performs any type of maintenance on electrical systems

Electrical System Violation Prevention Checklist

- Are only approved conductors and equipment used for electrical installations?

- Is electrical equipment free from recognized hazards that are likely to cause death or serious physical harm to employees?

- Are conductors spliced or joined using suitable devices or by brazing, welding, or soldering with a fusible metal or alloy?

- Are all electrical equipment parts that ordinarily produce arcs, sparks, flames, or molten metal enclosed or isolated from all combustible material?

- Is all electrical equipment marked with the voltage, current wattage, or other ratings as necessary?

- Are sufficient access and working space provided for all electric equipment to permit safe operation and maintenance of the equipment?

- Are electric equipment operating at 50 volts or more guarded against accidental contact by approved cabinets or other forms of approved enclosures?

- Are entrances to buildings, rooms, and other guarded locations containing exposed live parts locked and marked with warning signs for unqualified persons to enter?

- Are rooms or enclosures containing exposed live parts or conductors operated at over 600 volts, nominal, kept locked, or under the observation of a qualified person at all times?

Have questions? Looking for more information about OSHA Standards? We’re here to help.

KPA can help you develop a comprehensive EHS program that harnesses technology, best practices, and the concerted efforts of your workforce to maintain a safe and productive workplace.

Looking for more information and tips about OSHA’s 1910.303 standard?

KPA’s here to help.