Fall protection and prevention has been the most frequently cited Occupational Safety and Health Administration (OSHA) violation for several years now, which means, what industries are doing to address the issue isn’t working.

It’s easy to ignore but doing so puts everyone at significant and unnecessary risk for workplace slips, trips and falls. Keep your business and employees safe from lower level falls by following these recommendations.

Review the Rules

OSHA has aligned general industry standards with those already established for construction, though some differences remain.

On top of federal regulations, 28 states have their own regulatory frameworks for fall prevention that must meet or exceed federal standards. If you live in a state with its own plan, you need to know where it applies.

Remember the Hierarchy of Controls to Prevent Falls

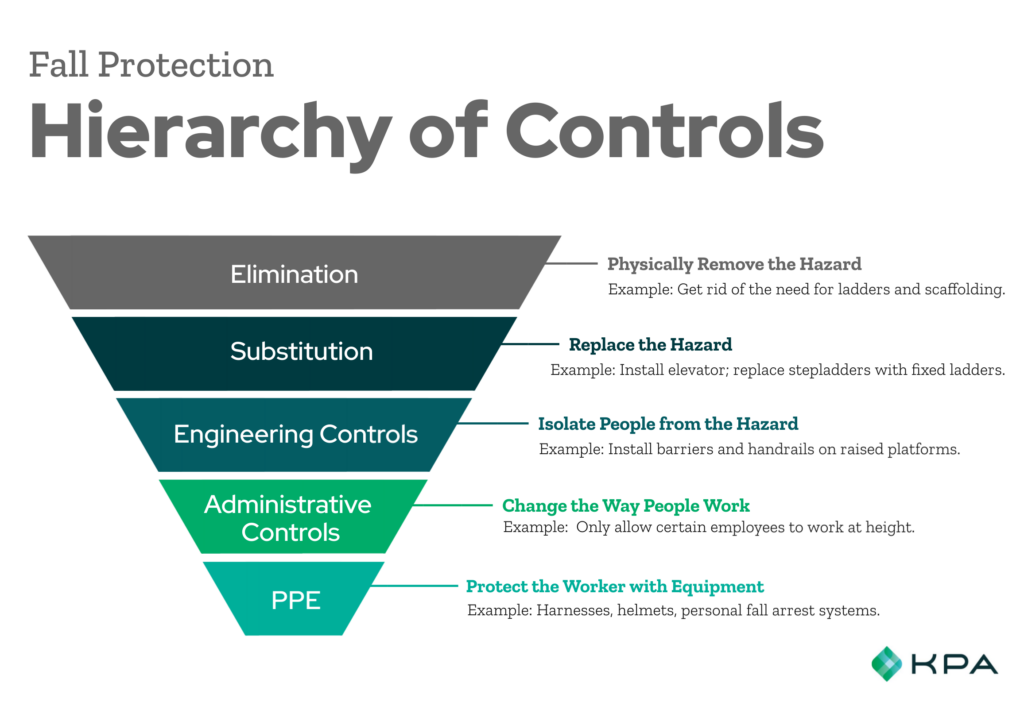

Falls are a straightforward problem with a straightforward solution—the same solution for every occupational safety problem: the hierarchy of controls.

A hierarchy of controls is an approach to environmental safety that structures protective measures into 5 stages, in order of most to least effective:

Find and Eliminate Fall Risks

The first line of defense against falls is identification and elimination, and you should always ensure:

- A competent member of your staff regularly assesses your facility for fall hazards. This person needs the authority to take corrective measures to remove or mitigate hazards.

- All of your employees understand their safety roles via required safety and health compliance training.

- Make “good housekeeping” a universal responsibility.

- Keep it a regular discussion topic at monthly meetings.

- Practice daily walkthroughs of a specific department, completed by an employee from a different department.

Use Passive Engineering Controls and Fall Restraint Systems When Needed

When a fall risk can’t be eliminated ensure warning signage and planned passive engineering controls, like guardrails, are at the ready wherever they are needed. Some passive protections, like guardrails, might be expensive to install but they’re a lifesaver and worth the investment. Use a fall restraint system when your employees are working near an unprotected edge or side. They can’t fall to a lower level if a restraint system keeps them from reaching that unprotected edge and tumbling over. Every system requires a body harness and lanyard attached to an anchor point. When a work area is clearly defined, a fixed single point anchor is appropriate. Where workers need to roam freely, like a rooftop, a horizontal lifeline is more appropriate.

Use a fall restraint system when your employees are working near an unprotected edge or side. They can’t fall to a lower level if a restraint system keeps them from reaching that unprotected edge and tumbling over. Every system requires a body harness and lanyard attached to an anchor point. When a work area is clearly defined, a fixed single point anchor is appropriate. Where workers need to roam freely, like a rooftop, a horizontal lifeline is more appropriate.

The Last Line of Defense: Fall Arrest

If a fall threat can’t be prevented through elimination, mitigation or restraint, a fall arrest system may save a worker’s life. The equipment is designed to withstand the force of a fall by controlling it and preventing the worker from striking the surface below

By law, a personal fall arrest system (PFAS) must use an anchor point able to withstand a downward force of 5,000 lbs. or the system must be supervised by a “qualified person” who has designed the system’s ability to arrest a fall’s downward force by a safety factor of 2. The PFAS must limit maximum arrest force—the most force that the person attached to the system will experience—to 1,800 lbs. The “qualified person” designation is one of the highest debatable definitions and one of the most overlooked requirements of the regulation, but should be a professional engineer with experience in designing PFASs.

Like restraint systems, employees must be trained to understand the requirements and proper safety compliance before using a personal fall arrest system (PFAS). They must inspect both the full-body harness AND the fall restraining hardware before each use. It is crucial that the employer and employees follow the instructions of the design.

PFAS is the last line of defense and should only be used where a worker’s job assignment makes it impossible to avoid an unprotected edge. If your worksite requires a PFAS to mitigate the fall hazard, then ensure the system is designed by a “qualified person.”

Understanding your responsibilities under the code of federal regulations and enacting policies to maintain the OSHA safety standards is a crucial step, however, the single most important step you can take is to actively identify, prevent, and mitigate fall hazards.