Do you know everything you need to know about the 10 most frequently cited Occupational Safety and Health Administration standards? In this series, we’re exploring the most common OSHA violations, one by one. Keep reading to learn about OSHA’s ladder safety requirements.

OSHA Ladder Safety: What It Is

OSHA definition:

“Working on and around stairways and ladders is hazardous. Stairways and ladders are major sources of injuries and fatalities among construction workers for example, and many of the injuries are serious enough to require time off the job. OSHA rules apply to all stairways and ladders used in construction, alteration, repair, painting, decorating and demolition of worksites covered by OSHA’s construction safety and health standards.” (Source)

Simple definition:

Ladders are dangerous. OSHA has specific rules about using ladders and working near ladders, as well as how ladders should be designed.

Check it out:

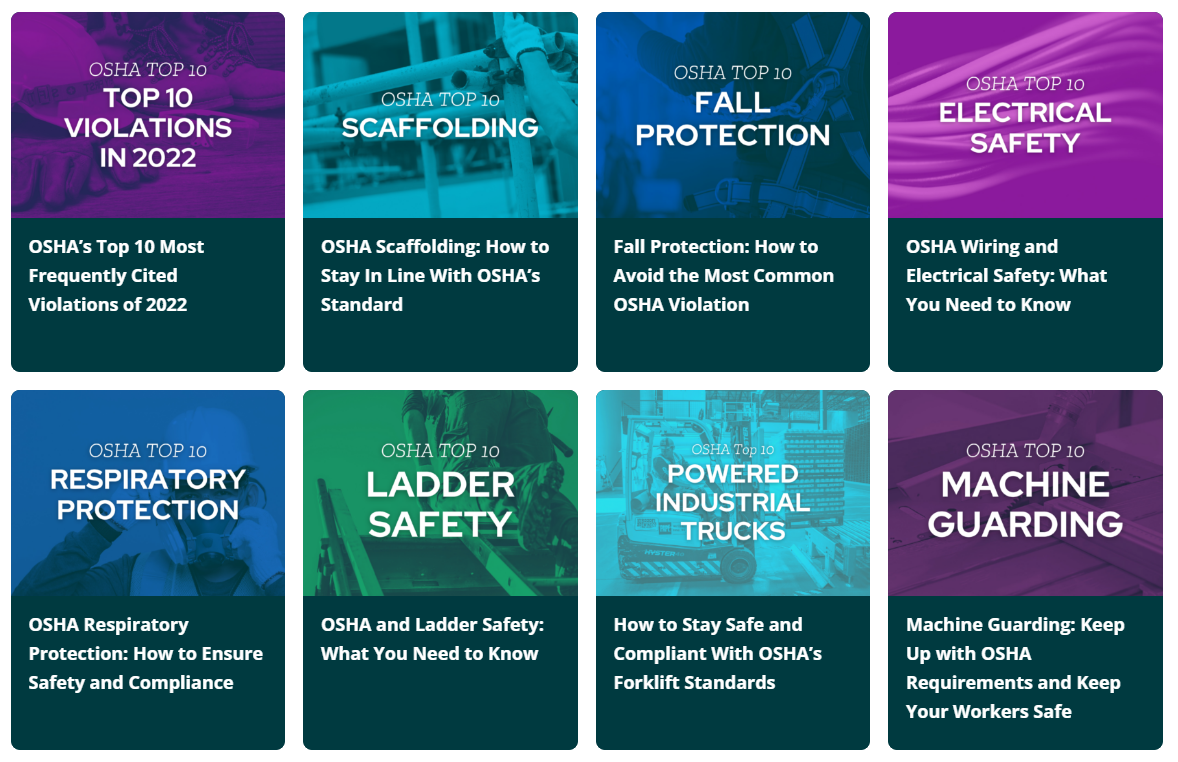

Read up on all of the top violations in the OSHA Top 10 Resource Hub

In general, there are three categories of ladders used in the workplace:

1. stepladders

2. portable ladders, including self-supporting (foldout) ladders and non-self-supporting (leaning) ladders

3. fixed ladders

OSHA has general rules that apply to all ladders, as well as specific regulations for each kind of ladder. Rules cover issues such as the following:

- how much weight a ladder can bear

- the angle and position of a ladder

- the spacing and design of ladder rungs, cleats, or steps

- how to use two or more ladders together to achieve additional height

- ladder care and maintenance

Why OSHA Ladder Safety Violations Happen

Most ladder-related injuries and deaths are falls. Perhaps a worker slips on a wet rung of a fixed ladder erroneously stands on the top rung of a step ladder and loses their balance, or comes crashing down with a poorly-supported portable ladder. Each of these is an example of a preventable incident—and an OSHA violation.

In fact, many OSHA violations related to ladders come down to simple misuse and mis-measurement. Oftentimes, it’s unintentional. Other times, it’s willful—a worker or supervisor choosing to ignore basic safety precautions because they’re in a rush or believe the rules are unnecessary.

One of the most common issues is side rail height. Keep in mind that when a portable ladder is used to access an area out of reach, the side rails must extend at least three feet above the upper landing surface. Too often, a worker or supervisor will overlook this rule because the ladder seems tall enough to provide access—regardless of whether the side rails reach three feet.

Another common violation is using the top of a stepladder as a step. No worker should ever sit, stand, or climb on the top platform of a stepladder.

Violations also happen when workers use ladders for unintended purposes, such as scaffolding, bracing, or as a work platform.

Finally, many violations involve the use of ladders with structural defects. A cracked, bent, rusty, or broken ladder is too hazardous to use. Workers should also never use a ladder built without proper support or grips, nor any ladder that is wet, oily, or greasy.

What You Stand to Lose When Ladder Safety Violations Happen

Direct costs: OSHA penalties can exceed $15,000 per violation—and as much per day for every day the issue hasn’t been fixed by OSHA’s deadline. The fine for a willful or repeated violation can be 10 times as much.

Indirect costs:

- workers’ compensation claims from workers who have fallen and sustained injuries

- lost productivity due to injuries caused by falls

- expensed related to replacing equipment damaged or broken due to falls, falling objects, or improper ladder use

- legal and compliance fees

- decreased morale

- negative publicity and reputational damage

Signs You’re at Risk of a Ladder Safety Violation

Construction professionals—especially roofing, framing, siding, and painting contractors—are at higher-than-average risk for falls and other ladder-related incidents.

The pressure to get the job done as fast and cheaply as possible can compel workers to ignore basic ladder safety and overlook issues on the worksite.

If there are few high-quality ladders around, workers may rely on shoddy equipment and makeshift solutions.

If you’re using ladders in an outdoor environment where it’s raining or just rained, or if people are working around liquid substances such as oils and paints, the potential for slips and falls increases.

How to Avoid a Ladder Violation: Your Prevention Checklist

The markings are most likely there for a reason.

Finding an issue before it can cause an injury is the key to staying out of OSHA’s crosshairs.

Rungs, cleats, or steps must be parallel, level, and uniformly spaced. Rungs should be spaced between 10 and 14 inches apart. For extension trestle ladders, the spacing must between 8 and 18 inches for the base, and 6 and 12 inches on the extension section. Rungs should be shaped so that a worker’s foot doesn’t slide off or skid.

Portable ladders must be able to bear at least four times the maximum intended load. An extra-heavy-duty metal or plastic ladder should be able to bear 3.3 times the maximum intended load.

Ladders should be kept clean of any water, oil, grease, or other substances that could cause slipping.

A self-supported portable ladder should be folded out all the way before anyone uses it. Non-self-supporting ladders should be positioned at such an angle that the horizontal distance from the top support to the foot of the ladder is approximately 1/4 the working length of the ladder (1/8 for wooden ladders constructed on the job). The locks on an extension ladder should be properly engaged prior to use. Every ladder should be placed on a stable and level surface, or otherwise secured in place. Ladders should not be fastened together unless they’re built for it. When two or more ladders are used together to achieve their combined height, there should be a landing platform between them. The area around the top and bottom of a ladder must be kept clear.

Try a mix of online and in-person training to make sure everyone understands how to stay safe. Here’s a sample

You Don’t Have to Manage Your OSHA Requirements Alone

Have questions? Looking for more detailed OSHA compliance guidance?

KPA is here to help.

To truly protect your workforce and bottom line, you’ll need in-depth information—and not just about OSHA’s top 10, but every potential hazard that exists in your organization. You’ll also need to conduct a thorough evaluation of your facilities to identify current gaps and risk areas.

KPA’s unique combination of software, training, and consulting services can provide the coverage your people and your organization need. For more information and guidance about preventing a fall protection violation, please contact us.

Related Content

Explore more comprehensive articles, specialized guides, and insightful interviews selected, offering fresh insights, data-driven analysis, and expert perspectives.